Shipbuilding technology is constantly evolving and with it shipbuilding materials and ship design. The application of laser cutting machines in shipbuilding has a unique nature, which is also related to the actual application of the ship itself. The high precision cutting and high plasticity characteristics of laser cutting machines are highly compatible with the shipbuilding industry. What are the advantages of laser cutting machines in the shipbuilding industry?

Reduce costs

At present, the ship manufacturing industry hull-plate undercutting methods mostly use flame cutting, plasma cutting, shearing and bending machine processing, and laser cutting. Laser cutting avoids the occurrence of uneven trimming quality caused by setting trimming margins on the plate in order to ensure assembly clearance when plasma is used for plate undercutting and by manual trimming. This reduces the relative workload, production cycles, and labor costs.

Precision cutting

The hull plate cut by laser cutting has good quality, good verticality of the cut surface, no hanging slag, a thin oxide layer, smooth surface, no secondary processing and can be directly welded. Small thermal deformation and high accuracy of curve cutting. Reduce the working hours. The cutting of precision ship plates is achieved without obstacles. As the hull structure requires a wide variety of profiles, the corresponding need for a 10,000-watt laser cutting machine equipped with an intelligent CNC-controlled laser cutting head that can achieve multi-angle and multi-directional cutting.

Fast shipbuilding and precision shipbuilding

The use of laser cutting machines for the cutting of materials can effectively reduce the secondary trimming process on-site and improve product quality. In recent years, the main development trend of the shipbuilding industry has gradually moved towards "fast shipbuilding" and "precision shipbuilding", and laser cutting technology has developed rapidly, accounting for more than 70% of the entire laser processing industry. The shipbuilding industry is mainly based on steel plate materials, and the use of laser cutting of plates greatly reduces the production cycle and saves costs compared to the traditional punching process.

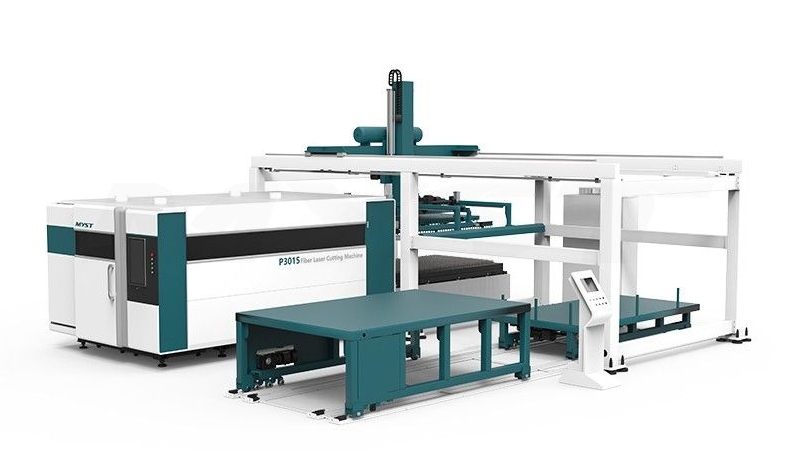

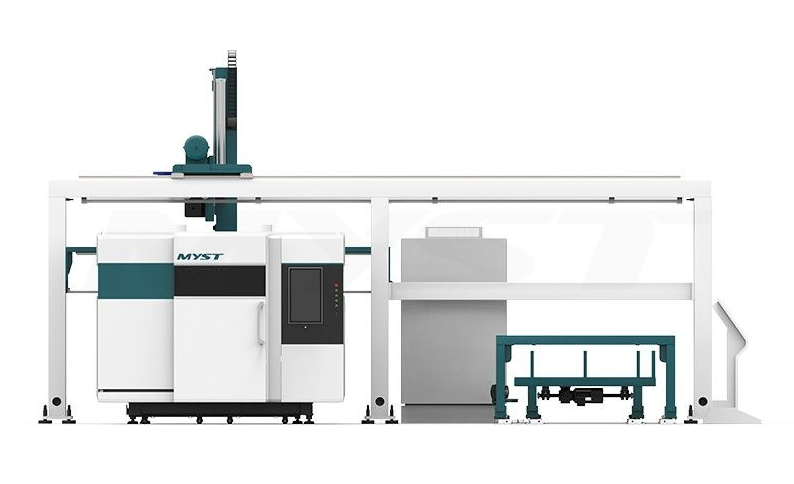

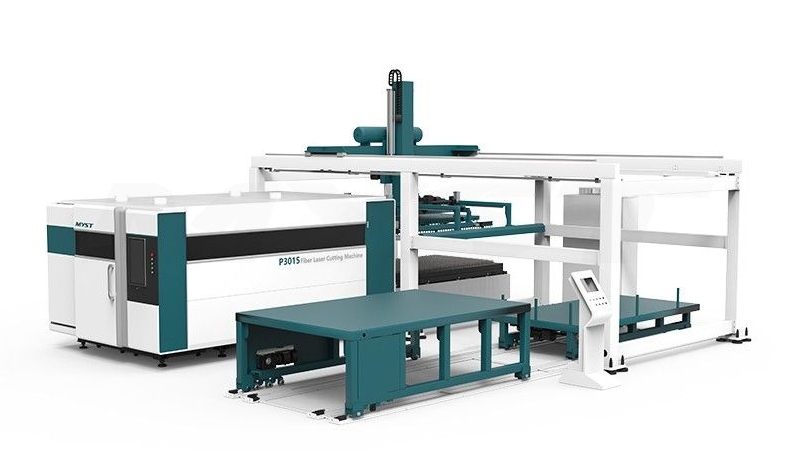

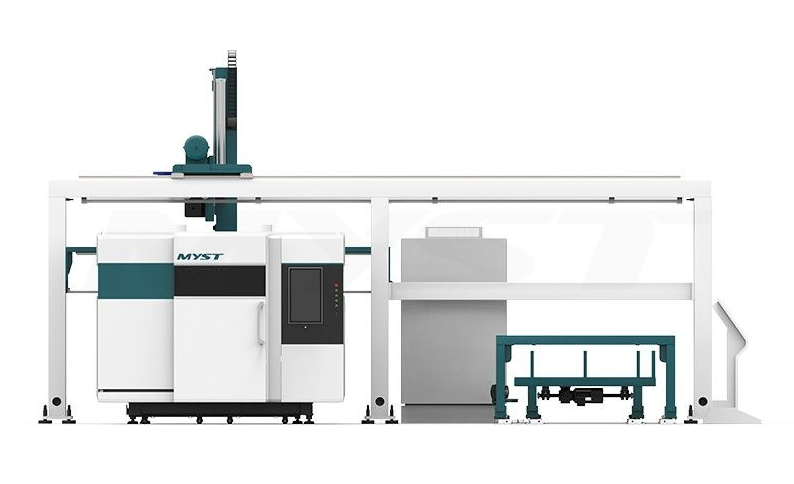

Intelligent production is more suitable for the shipbuilding industry

The combination of laser cutting machines with CNC and robotic machines helps users to achieve intelligent, flexible production. Laser cutting machines with hydraulic lift-assist loading mechanisms and lift-exchange platforms enable flexible loading and plate fine-tuning, fast cutting, and reduced non-productive time. Combined with the highly intelligent CNC bus system, the laser cutting machine enables changes to the cutting process settings, real-time monitoring of the cutting status, and full testing and recording of the cutting data parameters. It is an important aid for engineers to continuously optimize the cutting process parameters and optimize the cutting effect of the workpiece.

Laser cutting machines will be used in more shipbuilding enterprises in the future, and high-power laser cutting machines are bound to be the future trend. We are a laser cutting machine supplier, please feel free to contact us if you need them.