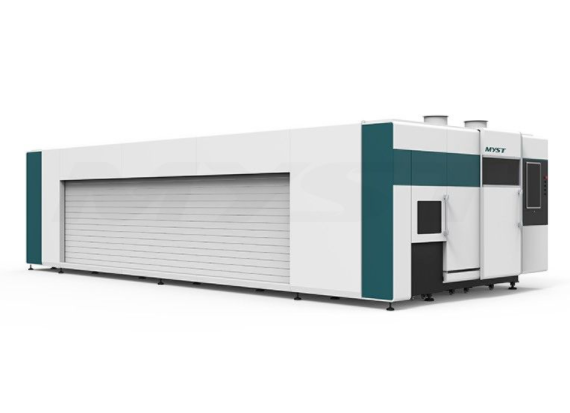

Laser cutting machine as a common means of processing in the modern manufacturing industry, breaks the traditional way of processing, with a new way of cutting in a wide range of industries are widely used. Users who understand fiber laser cutting machines know that they must use auxiliary gases in the cutting process. That is why many people are more concerned about the choice of auxiliary gases for laser cutting machines.

Why do you need to add auxiliary gas when the laser cutting process?

Before figuring out how to choose the auxiliary gas, the first thing to understand is why we need to use auxiliary gases and the role of auxiliary gases. The use of auxiliary gases in addition to blowing away the coaxial slag in the cut, but also to cool the surface of the object to reduce the heat-affected zone. Cooling the focusing lens prevents soot from entering the lens holder and contaminating the lens and causing it to overheat. In addition, some cutting gases can also play a role in protecting the base material. The choice of gas pressure and type has a significant impact on the cutting process. The type of auxiliary gas selected will have an impact on the cutting performance including cutting speed and cutting thickness.

Laser cutting machines can use the auxiliary gases

Nitrogen

Some metals cut with oxygen will form an oxide film on the cutting surface, while the use of nitrogen can avoid the appearance of the oxide film and oxidation-free cutting. The oxide-free cutting surface has the characteristics of being directly fusible and paintable and corrosion-resistant. The end face of the cut is white.

Mainly used: There are stainless steel, electroplated steel plate, brass, aluminum and aluminum alloy, etc.

Oxygen

Mainly used for laser cutting machine cutting carbon steel. Oxygen reaction heat not only can significantly improve the cutting efficiency but also the resulting oxide film will also improve the absorption factor of the beam spectrum of the reflected material.

Mainly used: calendered steel, calendered steel for fusion construction, carbon steel for mechanical construction, high tensile plate, tool plate, stainless steel, electroplated steel plate, copper and copper alloy, etc.

Argon gas

It is an inert gas used in laser cutting machines to prevent oxidation and nitriding and can be used in fusion welding. Compared with other processing gases, the price is higher and will increase the cost accordingly. The end face of the cut is white.

Mainly used: titanium and titanium alloy, etc.

Air

Since air can be supplied directly by an air compressor, it is very cheap compared with other gases. Although air contains about 20% oxygen, the cutting efficiency is far less than oxygen, and the cutting ability is similar to nitrogen. Trace amounts of oxide film will appear on the cutting surface but can be used as a measure to prevent the coating layer from peeling off. Yellowing of the cut end surface.

Mainly used: aluminum, aluminum alloy, stainless steel, brass, electroplated steel and non-metal, etc.

The gas must be selected according to the characteristics of the product during the cutting down process. Many gases can be used universally, focusing on the cost of cutting and the requirements of the product. For example, when cutting stainless steel materials, when the quality of the product or surface quality is not very high requirements, such as cutting products later need to go through painting and other technological processes, you can use air as the cutting gas, which can reduce a lot of costs. When the cut product is the final product, there is no subsequent process, it is necessary to use protective gas, such as craft products, etc. We are a laser cutting machine supplier, please feel free to contact us if you need them.