+8613256742787

Metal laser cutting machine , Fiber laser cutting machine , Laser Cutting Machine Supplier , Laser Marking Machine , Fiber Laser Marking Machine ...

Fiber Laser Cutter

Sheet Metal Laser Cutting Machine

Sheet & Tube Metal Laser Cutting Machine

Fiber Laser Tube Cutting Machine

10KW+ High Power Laser Cutting Machine

H-Steel Laser Cutting Machine

Small Metal Laser Cutter

Fiber Laser Cutting Machine more and more popular in these years , What you need to know order a good metal laser cutter? What is the most important for order a cnc metal laser cutter? how a good metal laser cutter machine manufacturers produce processing ? Why different manufacturer's fiber laser cutter price big different ?This guide will helping you.

In the past few years we usually use plasma cutting machine , co2 metal laser cutter or other metal cutting machine , but in 2024 the most popular is fiber laser cutter .this type metal laser cutter have more faster speed more stability working .

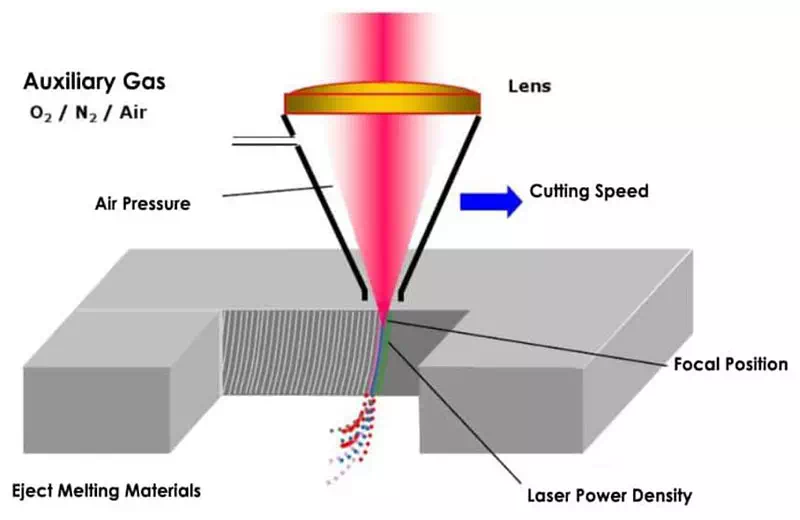

Fiber laser cutter Is one kinds of metal laser cutter, fiber laser metal cuting is a laser processing that use fiber as medium cuts metal into a desired shape (When the laser beam irradiated onto the surface of the metal sheet , energy released melt or vaporize the metal sheet ,slag blow away by the gas) ,most of the manufacturers can produce1kW, 2kW, 3kW,6kW,8kW fiber laser cutter, but more big power fiber cutting machine few manufacturers can do it well , LXSHOW LASER was one of the few manufacturers in china that can produce 10kW,15kw,25kW fiber optic laser cutter.

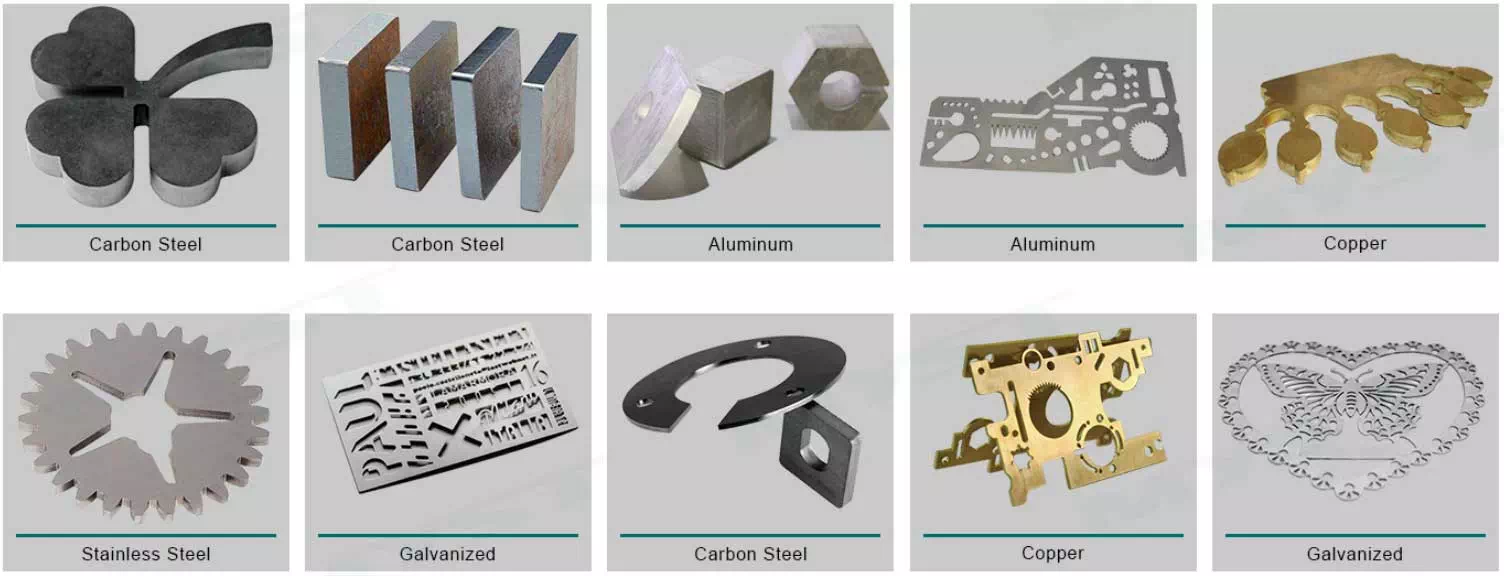

Fiber cutting machine is mainly used for cutting SS, CS, galvanized steel, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and almost all the metal materials.

Fiber laser cutter used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, construction machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing , Decoration, advertising, metal external processing, kitchenware processing and other manufacturing and processing industries.

1.Economical; extremely high electro-optical conversion efficiency, energy saving and environmental protection.

2. Practicality; the precision of the machine to cut the workpiece is high, and it can reach a precision of less than 0.03mm. Compared with traditional processing tools, it eliminates the secondary grinding process, reducing the workload of personnel and shortening. Delivery. In addition, its processing materials and thickness are very extensive, fiber laser cutting machine for stainless steel, copper aluminum, carbon steel, aluminum alloy, etc. are no problem.

3. Efficiency; efficiency determines economic benefits. The cutting speed of our machines can reach 100 meters per minute, which means that the efficiency of completing a small workpiece is only a few seconds. Compared with traditional equipment such as plasma or wire cutting, steel laser cutter speed is much faster.

4. Excellent beam quality: smaller focus spot, finer cutting lines, higher work efficiency and better processing quality;

5. Extremely high cutting speed: twice as much as the CO2 laser cutting machine with the same power;

6. Extremely high stability: The world's top imported fiber laser is used for stable performance.

7. Extremely low cost of use: The power consumption of the whole machine is lower than that of CO2, which saves production costs

8. Extremely low maintenance cost: no laser working gas; optical fiber transmission, no need for reflective lens; can save a lot of maintenance costs;

9. Convenient product operation and maintenance: optical fiber transmission, no need to adjust optical path;

Usually we divide them into 3 types , you need choose it according to your working not just condsider the machine price

1.Sheet Metal Laser cutter

2.Sheet & Tube Metal Laser cutter

3.Professional Tube Metal Laser cutter

What is the purpose of buying a good laser cutting machine steel? Each manufacturers work is different. It is important analysis your own situation.

Manufacturers who do not have a fiber cutting machine generally subcontract work to one or several workshops with such processing capabilities. Compliance with your process requirements is most important for you. If you have more flexibility in the process requirements and delivery time, you can consider outsourcing your work. If you choose to outsource, you need to calculate the cost of outsourcing and the cost of your own processing. If the workload is relatively large, it is a wise choice to buy a fiber laser machine by yourself, which saves costs and controls the processing technology and delivery time.

CNC punching is a good choice for processing standard parts

Part edge accuracy require not high, plasma cutting machine also a good choice.

After analyzed through the previous steps that you really need a fiber laser cutter, if you want choose a good quality fiber laser cutter you need to learn detail of the core components for the fiber cutting machine, you also need learn how the good quality machine produce processing. Here is detail of the core component and How a good Fiber laser cutting machine processing.

Fiber laser cutting machine body and processing technology, machine body impact inertial force during the movement of the machine . LXSHOW laser specially hires the Italian designer to design the machine bed. The machine base part usually adopts the weighting design

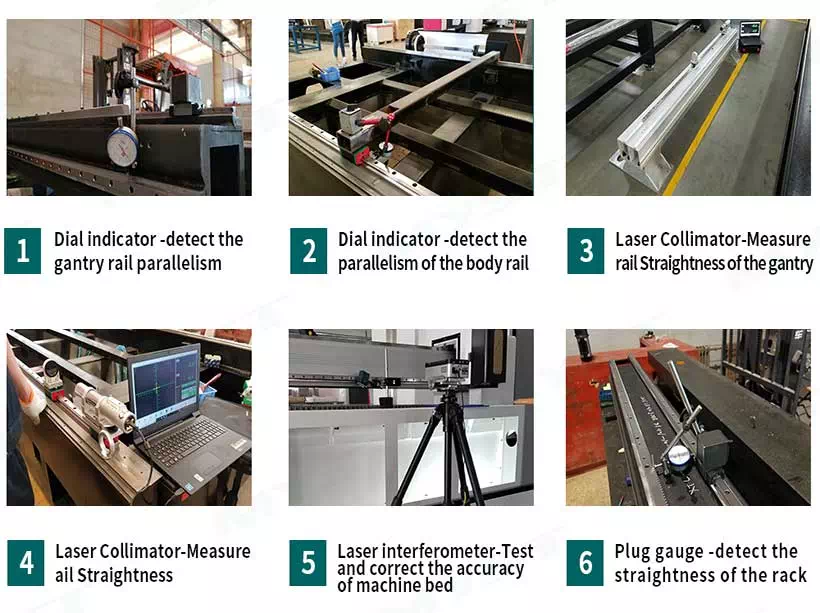

In addition, the bed processing technology of the laser cutting machine for sheet is the core of the entire bed processing. The processing technology also determines the accuracy of the machine bed assembly. Every machining process is essential,saving the process, which makes the machine price very competitive.but the machine accuracy and the long-term use accuracy can not meet the customer's requirements.

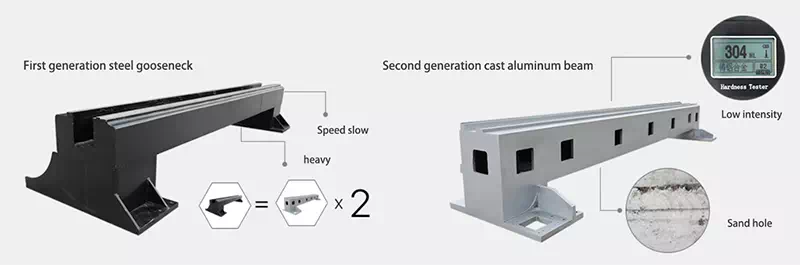

The first generation of the fiber laser cutter is steel gantry, weight is heavy and speed is slow, the second generation of fiber laser machine is cast aluminum gantry, aluminium gantry is light in weight but strength is low, casting is easy to appear holes.

Third-generation gantry is manufactured by aerospace standard cast aluminum gantry , it was extruded with a 4,300-ton press. After aging treatment, the hardness can reach T6, which is the strongest hardness of all gantry.

For a metal laser cutter the most important and expensive part is the metal cutting machine source,if this part have any problem fiber laser cutting machine 1530 will stop working . for the fiber laser source select the most important not the price of the source, select a good quality fiber source is the most important .In china we have two famous brand fiber source MAX and Raycus.this two brand have good quality you can choose one brand from it .

After choose the brand of the fiber source , the second step is which power of the fiber source you need , this depend on your working here is the fiber source cutting ability of the fiber source, pls kindly check it .

Tip : as the laser cutter parameter if you want cutting 6mm Carbon Steel How much power you choose ?

6mm is 500W Laser source Max cutting thinkness , if your most working is 2-3 mm very little working is 6mm , 500W is a good choice for you , but if your most working is 4-6mm you need choose 750W or 1000W. now it not have a big price different between 750W and 1000W . 1000W is a good choice for you .

Maybe your working have more complicate than this , Contact us we will give you the best choice.

Photo of the laser cutting machine source.

In china have two famous fiber laser cutting head brand raytools and WSX . if you order the laser metal cutting machine from china it is the best choice choose the head brand from this two brand .

As before 5.1 description we have a strict structure processing

1.Pearl cotton and cling film packaging

2.Water chiller and machine parts was packing in wooden and put one machine frame

3.Aluminum foil sleeve packaging with cling film wrapping

4.Put the machine on the Steel and plywood base

1.18 hours online service

We have a perfect sale team of our fiber laser machine , if you have any problem before order the fiber laser cutter , kindly contact us we will do our best with a quickly feedback.

2.Engineer support

We have one pre-sale engineer team cooperation with our sale team for customer questions of the fiber laser machine.

3.Samples Free making

If you don’t sure about weather our fiber laser machine can do your working , we can make the samples for you free.

4.Customer machine design

We can do our fiber laser cutter as the customer need , talk with our sale detail of you need we have engineer design the Heterosexual machine for you free.

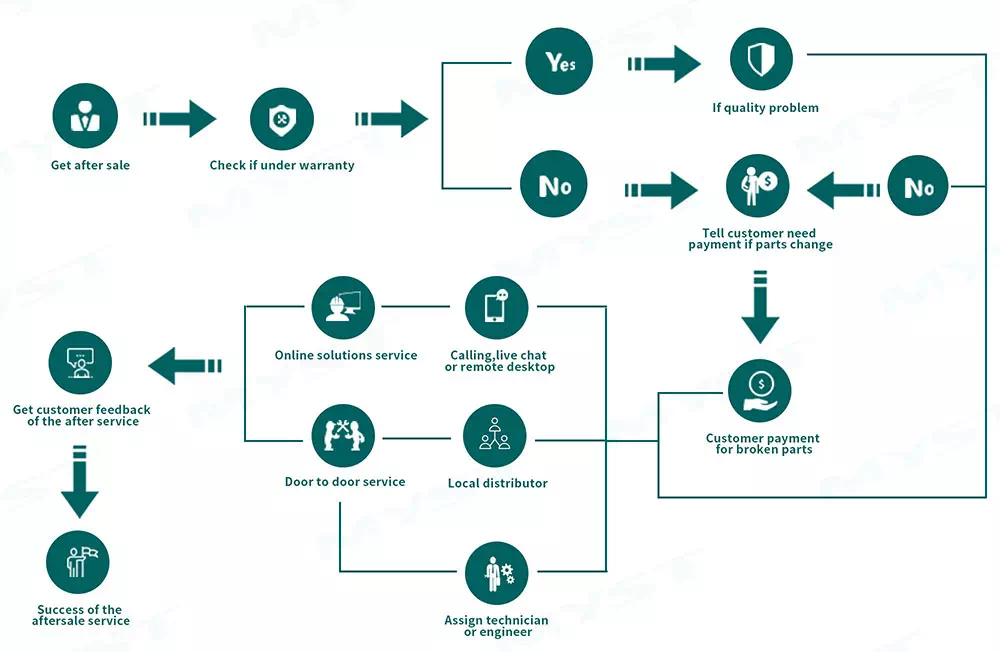

You need choose a manufacturer with reliable after-sales service. The reliable service is not to let you compare the size of the manufacturer or which machine more beautiful, Choosing a professional manufacturer is critical.

1.3 years for whole fiber laser cutter except consumable parts lens/mirror/nozzle

2.Free service for life

3.If the parts broken after warranty only payment Cost price and transport cost we will send the new one for you

4.If the fiber cutter problem can't solve we can provide after sale engineer to your place

1.which material you want cutting by the fiber cutter?( stainless steel , Carbon steel , Aluminium, cooper)

2.The Max thickness of the metal you want cutting ? the main thickness of the metal you want cutting ?

3.The Max size of your metal

4.How long time of the Fiber laser metal cutting machine need work every day ?

5.Your nearest seaport?

6.Your whatsapp ? then we can talk more detail online

1.Fiber laser cutter cost

2.Spare parts cost

3.Shipping cost and Port charges

4.VAT

5.Customs Cost

6.Installation training costs

Hoping this Ultimate Guide can helping you choose the best suitable fiber laser cutting equipment for your working

1. What is fiber laser cutting machine?

2. Main classification of the fiber laser cutting machine?

3. The main construction of fiber cutting machines and the best processing techniques

4. How to choose a right machine for your work

5. Detail of the core component for fiber laser cutting machine

6. How a good cutting machine processing ?

7. Fiber laser cutter Packing and Transport

8. LXSHOW Laser Pre-Sale service of our fiber laser metal cutting machine

9. LXSHOW After sale service of our fiber laser cutting machine

10. Warranty of LXSHOW Laser fiber laser metal cutting machine

11. If you want get a quotation of the machine what you need tell us

12. If you order the fiber laser cutting machine from china what you need calculate of the total cost

It is important to find a good fiber laser cutting machine supplier , a good fiber laser supplier have a very strict produce processing and every machine parts quality is good. If you have any problem of the machine it will be solve very quickly. LXSHOW LASER development Fiber laser cutter for 16year, we are one of the best fiber laser metal cutting machine from china.Choose LXSHOW LASER you will have get a perfect machine and perfect service.

Hope you can buy a suitable fiber laser cutting machine. If you have more questions, you can send an email or add our Whatsapp. We will be very happy to answer your questions!