Optical lens as a consumable in the laser cutting machine, as long as we use correctly in the daily work and good maintenance work, you can maximize the life of the laser. This reduces the number of lens replacements and thus reduces the cost of use.

Why do you need to protect the lens of your laser cutting machine?

When a laser cuts and heat treat materials, the work surface releases large amounts of gases and spatter that can cause serious damage to the lens. Laser cutting machines can easily expose the optics in the laser to suspended materials if they are not protected during laser processing. When contaminants fall on the surface of the lens, they absorb energy from the laser beam. On the one hand, the laser output power is reduced, so that the laser processing capacity decreases sharply. On the other hand, it generates heat, which can lead to damage to the lens itself and the optical film layer on the surface over time.

The only purpose of the cleaning process is to remove contaminants from the lens and not to cause further contamination or damage to the lens.

1. Blow the floating material off the surface of the element with an airball. This step is essential especially for lenses with microscopic particles and flocs. However, do not use unfiltered compressed air, because it contains oil and water droplets, which can increase the contamination of the lenses.

2. light cleaning of the lenses with acetone. The cotton ball dipped in acetone must be cleaned in the light and moved in a circular motion. The swab must be replaced once it becomes dirty. Cleaning should be done in one pass to avoid ripples. This grade of acetone is almost waterless, which reduces the possibility of contamination of the lenses.

3. If acetone does not remove all the contaminants, the next step is to use acid and vinegar cleaning. Acid and vinegar cleaning uses acid to dissolve the contaminants to remove them. However, it does not harm the optics. The cleaning procedure is the same as the acetone cleaning. Acetone is then used to remove the acid and vinegar and to dry the lens. It is necessary to change the cotton ball frequently to completely absorb the acid and hydrate.

The correct way to install the lens of the laser cutting machine

1. Do not use suction instruments to avoid scratching the lens surface.

2. It is best not to install the lens with bare fingers. Wear finger gloves or rubber gloves.

3. The operator should avoid talking over the lens and keep food, drinks, and other potential contaminants away from the working ring.

4. Do not touch the film layer when removing the lens and hold the edge of the lens.

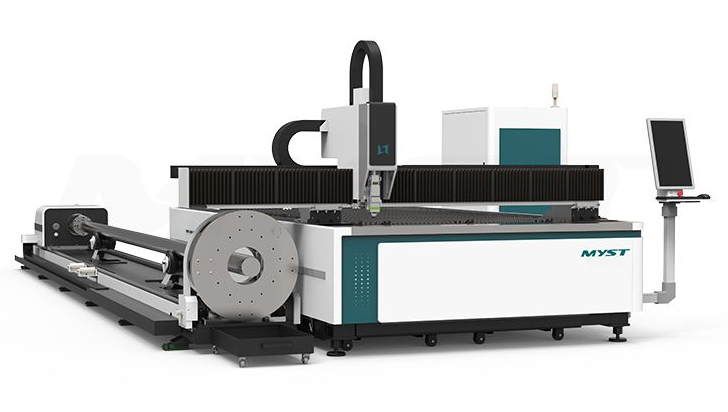

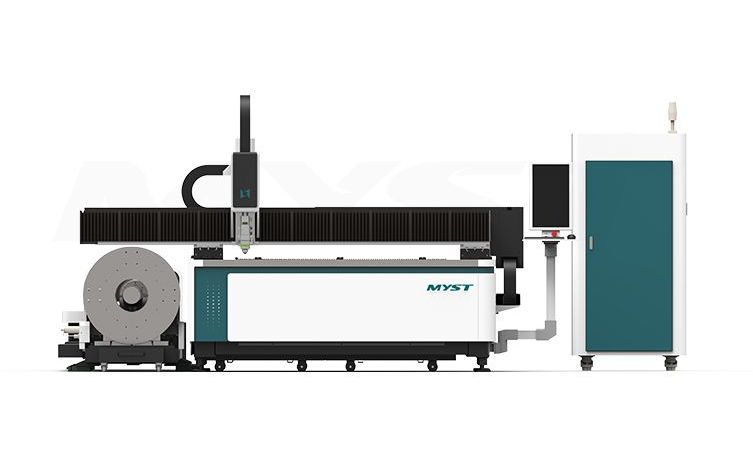

We are a professional laser cutting machine supplier, please feel free to contact us if you need them.