More than 8 million people fly a day, with more than 3 billion flights a year. This is a huge number that shows the importance of the aerospace industry. Moreover, as the industry develops and people turn their attention to space, it is clear that the needs and needs of the industry will continue to grow at the same time.Laser is a great invention of atomic energy, computer and semiconductor since the 20th century. Whether it is an airplane or other aviation equipment, it is under tremendous pressure from high altitude and there is absolutely no room for error in the manufacturing process. For this reason, lasers have great prospects in aerospace industrialization due to their high efficiency, low energy consumption, intelligence, and good processing quality.

Laser marking in aerospace applications

Safety and high quality are the primary considerations for aerospace and will never change. The aircraft consists of thousands of precision parts that need to identify labels, bar codes, serial numbers or the like. Laser marking marks are not damaged by other processes. Laser marking is not suitable for removal. Clearly visible, the aircraft is composed of many different materials. The most common forms are metals such as aluminum and titanium. Laser marking machines are very suitable. Processing of these materials.

High power laser welding applications

Titanium alloy is mainly used in aircraft. The main structural materials of aluminum alloy are mainly used in the main structural materials of launch vehicles and various spacecrafts. Compared with titanium alloy aluminum alloy traditional welding machine, laser welding has energy concentrated welding parts, small deformation, good welding quality and energy consumption. Small welding efficiency and other characteristics. Laser welding technology will soon replace the traditional welding technology used by aircraft to launch rockets.

Aircraft alloy siding welding: Aircraft alloy siding is generally laser-filled and welded. Aluminum and aluminum alloys are easy to form liquid aluminum at high temperatures. Liquid aluminum has good fluidity and is prone to bed-staying. Therefore, filler wire welding is generally used.

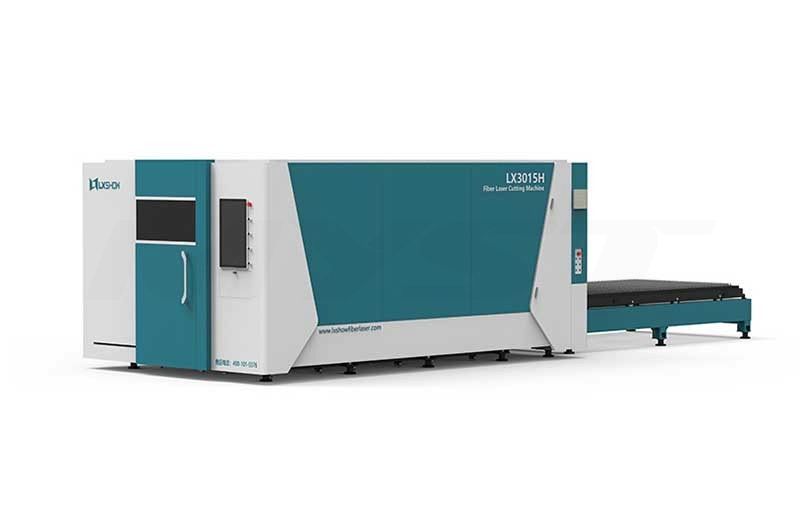

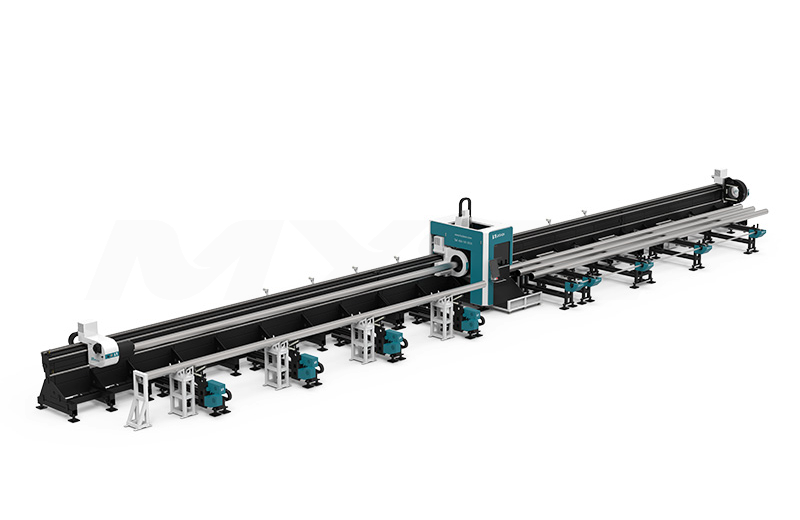

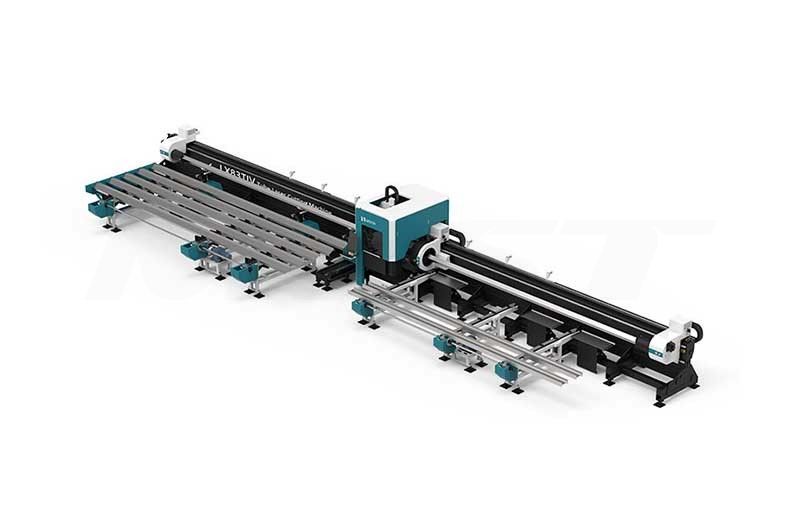

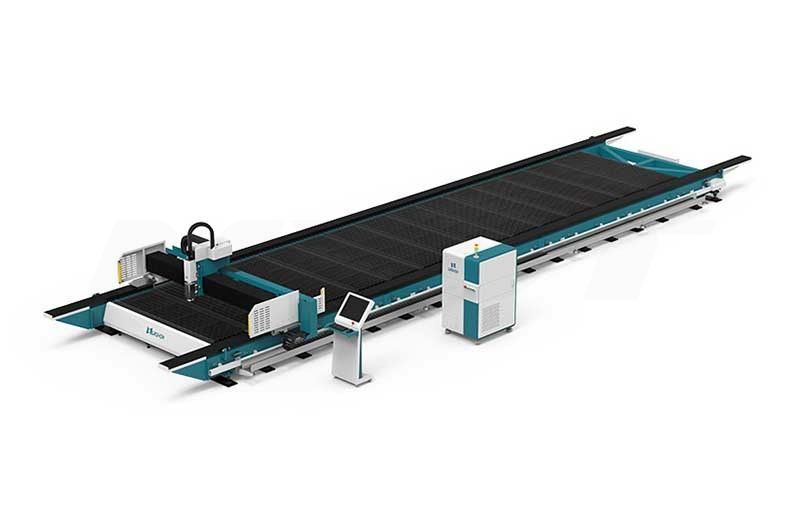

High-power laser cutting and punching in aerospace applications

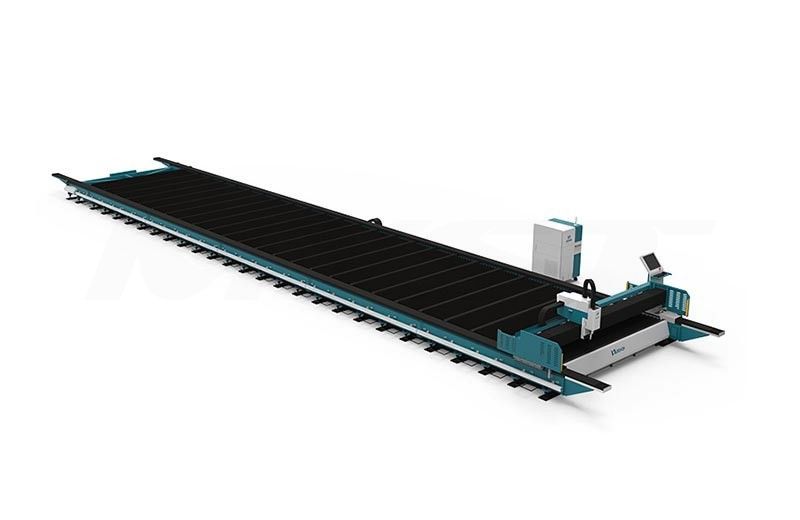

Laser cutting materials in the aerospace industry are titanium alloys, nickel alloys, chrome alloys, aluminum alloys, tantalum oxide, stainless steel, molybdenum titanate, plastics and composite materials. Laser cutting can be used to process aircraft skins, honeycomb structures, frames, Wing Bin, tail siding, helicopter main rotor, engine casing and flame tube. Laser cutting is now the fastest growing and mainstream fiber laser cutting machine.

Since the 20th century, lasers have become another great invention after atomic energy, computers, and semiconductors. It also plays an important role in aerospace industry, With the increasing awareness of environmental protection, it has brought enormous challenges to the development of the cleaning industry worldwide. Laser cleaning technology is one of the best in the development of various environmentally friendly cleaning technologies.

So what is laser cleaning technology?

Laser cleaning technology refers to the process of using a high-energy laser beam to illuminate the surface of the workpiece, causing the particles, rust and coating on the surface to instantaneously evaporate and peel off, thereby achieving a clean process.

For the airport, ensuring the normal take-off and landing of the aircraft is a very critical part. Because the friction aircraft tires contact the surface of the runway at high speed, high temperature causes the tire rubber to melt and adhere to the texture of the road surface.The aircraft runway rubber layer is continuously thickened,the friction coefficient of the road surface is reduced, which affects the braking performance of the aircraft and thus affects the safe landing of the aircraft. Therefore, the major airports regularly clean the runway every year to ensure that the coefficient of friction of the runway is not less than 0.5 to avoid accidents.

At present, the commonly used degreasing equipment in the industry includes ground milling machine and mobile shot blasting machine.

The ground milling machine can causes damage to the surface of the runway during the decreasing process;In the case of mobile shot blasting machine, there may be steel shots scattered on the runway. If it is not cleaned up in time, it also can cause damage to the aircraft.But it is easy to avoid the problems with a laser cleaning machine.

Next, let's take a look at our experimental data before we introduce the laser cleasing machine.

Cleaning experiment

We experimented with a Raycus 500W pulsed fiber laser with wavelength of 1064nm, pulse width of 130-160ns, Frequency of 20-50 kHz,laser core diameter of 200, and single pulse energy of 25mJ. In the experiment,cleaning speed of 20 mm/s was selected, and the rubber was cleaned under each energy condition by direct radiation, Finally,the experiment was successful.

Raycus 500W generator parameters are as follows:

| Object | Test condition | Value | Unit |

| Optical properties |

| Work mode | Pulse | / |

| Polarization direction | Random | / |

| Frequency | RR=10kHz Pmax | 200≤P≤220 | W |

| RR=20-50kHz Pmax | 500≤P≤520 |

| Power adjustment range | / | 10-100 | % |

| Center wavelength | RR=10-50kHz P=Pmax | 1064±5 | nm |

| Spectral width | RR=50kHz P=Pmax | ≤10 | nm |

| Output power instability | 5Hrs later/RR=50kHzP=Pmax | ≤5 | % |

| Pulse width | RR=10kHz P=Pmax | 80-110 | ns |

| RR=20-50kHz P=Pmax | 130-160 | ns |

| Single pulse energy | RR=20-50kHz P=Pmax | 25 | mJ |

| Pulse setup time | RR=50kHz P=0~90%Pmax | <200 | us |

| Pulse off time | RR=50kHz P=100%~10%Pmax | <100 | us |

| Frequency adjustable range | / | 20-50 | kHz |

| Red light output power | / | 0.1~1 | mW |

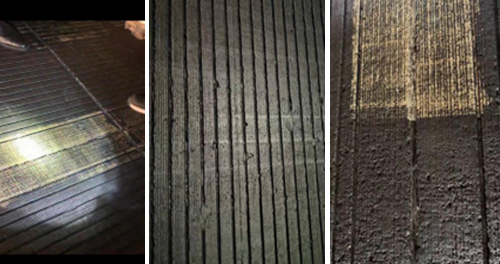

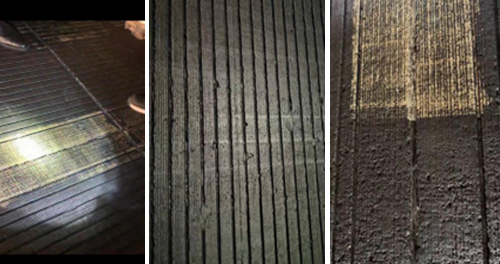

Comparison before and after cleaning:

In the actual cleaning of the airport runway, we need to use different energy movement speeds according to the actual situation of each airport runway to achieve the best cleaning effect.

The laser cleaning machine can effectively remove the tire rubber layer on the runway according to the depth of the airport runway black depth and does not cause any damage to the runway, and the environmental protection.

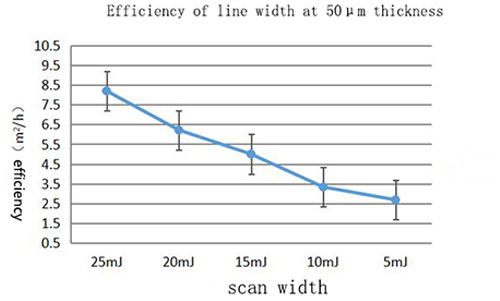

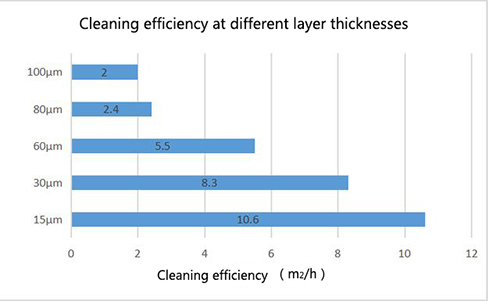

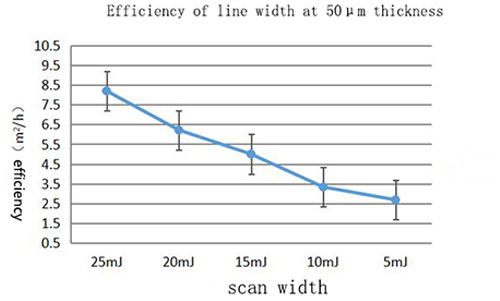

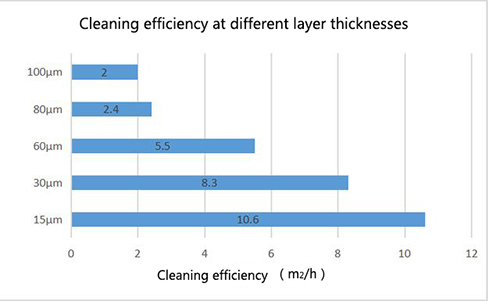

What is the relationship between laser single pulse energy and cleaning efficiency?

The higher the laser single pulse energy, the higher the cleaning efficiency. The following figure shows the relationship between the cleaning efficiency and the laser single pulse energy.

There are two critical values for laser cleaning, completely cleaning the energy boundary and the damage energy boundary. The cleaning efficiency is increased between the initial cleaning energy value and the complete cleaning energy value. As the laser energy increases, the cleaning efficiency increases continuously, and the boundary between the cleaning boundary and the damage energy is completely cleaned. The surface of the substrate will remain

100% clean without damaging the substrate, exceeding the damage energy boundary. The cleaning energy increases the damage to the substrate.