Laser technology has been widely recognized in medical and other related fields due to its many advantages. On the one hand, laser technology has led to further developments in basic medical research, laser diagnostics and laser therapy; on the other hand, it is playing an increasingly important role in the development and manufacture of medical devices.

The application of laser technology in medical equipment can be divided according to the type of laser equipment, that is, the application of laser marking machine, laser cutting machine and laser welding machine in the medical equipment industry.

1. Application of laser marking machine

Laser marking machine is mainly used in the packaging of products in medical treatment. Product packaging is the main means for consumers to understand products and discover the unique personality of products. It is also the main way for manufacturers to identify products. Compared with traditional ink printers, laser marking machines have the following advantages:

low cost. The printer often has nozzle clogging, which requires professional maintenance personnel and increases the cost of the machine to some extent.

High environmental protection. As people's awareness of environmental protection increases, the use of ink is clearly not meeting the requirements of low pollution.

High efficiency. The laser marking machine can realize high-volume pipeline marking with more accurate accuracy.

Unchangeable. Laser-marked markings must not be applied and tampered, and are not subject to wear.

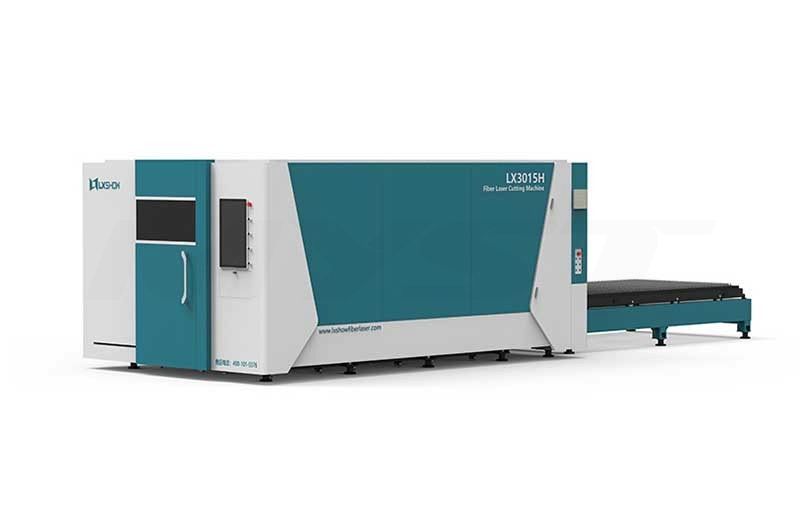

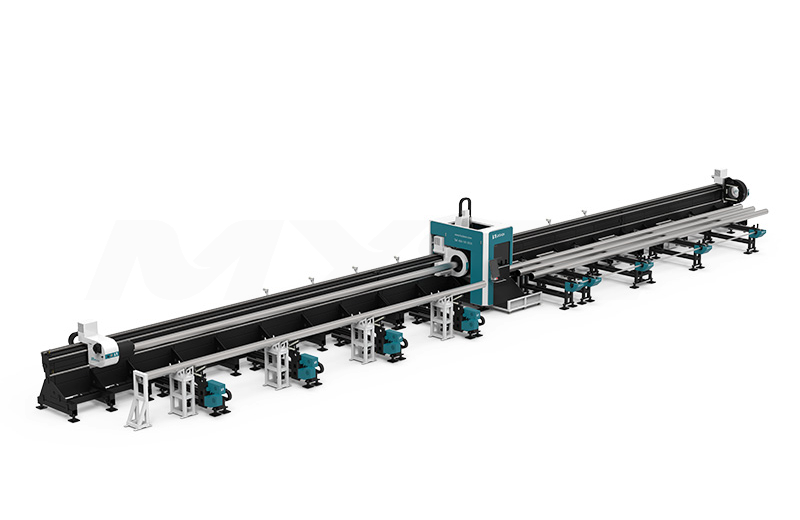

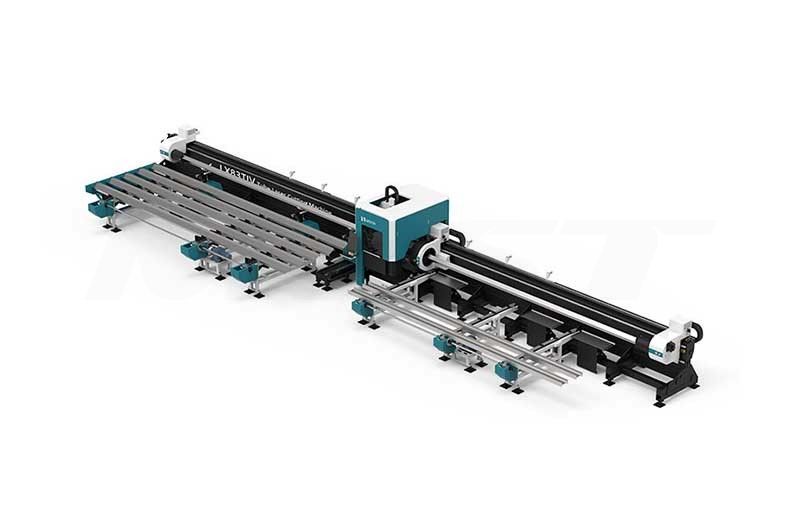

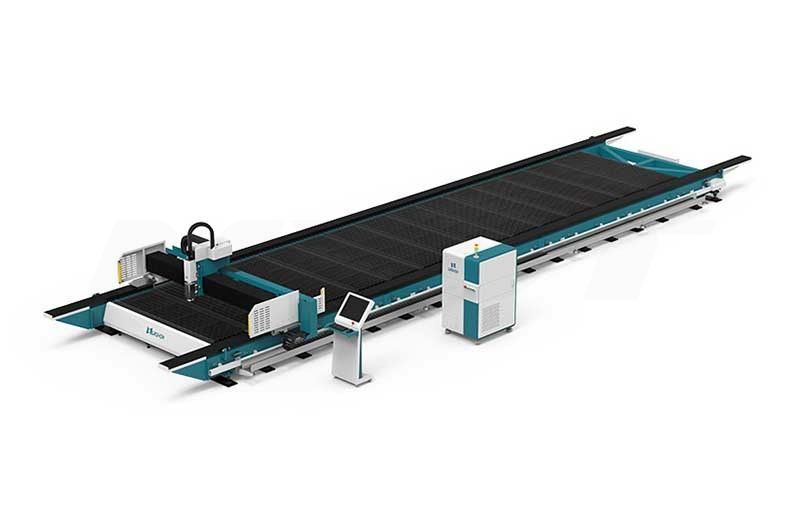

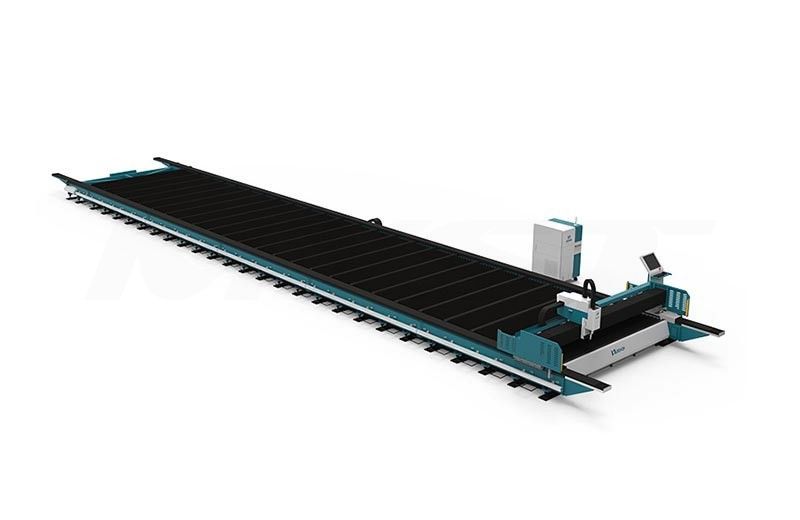

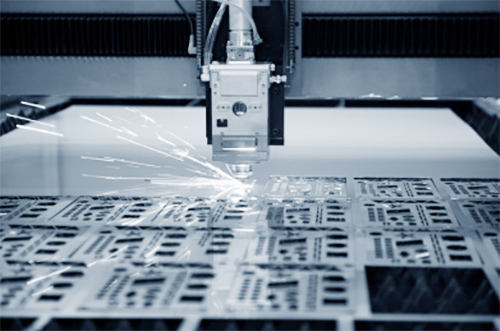

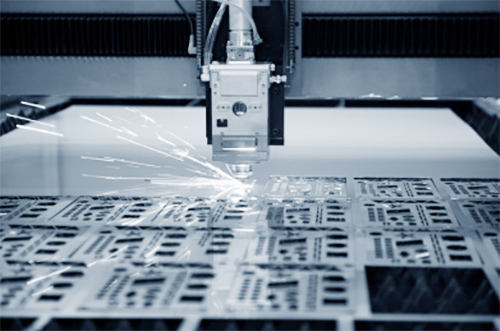

2. Application of laser cutting machine

Due to the particularity of medical devices, our requirements for precision, safety and even hygienic conditions are increasing. Therefore, in the manufacture of medical devices, the choice of process manufacturers have become the focus of attention in the industry. The traditional cutting process has difficulty in controlling safety and smoothness, and the precision is far from the laser cutting products.

The laser cutting machine uses a high power density laser beam to act on the surface of the material to melt or vaporize it, and then blows off the molten or vaporized material in the slit by high pressure gas to achieve the purpose of cutting the material. Laser cutting is a hot-working property. In a short period of time, materials can be processed to thousands to tens of thousands of degrees Celsius, which can meet the requirements of one-time molding of processed products. In addition, the high power density laser beam applied by the laser cutting machine has a small diameter, and the slit width can be accurate to two decimal places, thus ensuring high precision of cutting. At the same time, since the laser cutting process is non-contact processing, there is no possibility that the workpiece is scratched during the processing.

3. Application of laser welding machine

Laser welding is increasingly used in various fields of medical devices due to its advantages of local heating, precision machining, and non-contact heating. Compared with the traditional welding technology, the laser welding process produces almost no slag and debris, and it is not necessary to add any adhesive during the welding process, so the entire welding operation can be completed in the clean room.

Laser welding technology is the most common connection and sealing technique for implantable medical devices, usually assisted with inert gases. At present, many active implantable medical devices, passive medical devices, cardiac stents, etc. are all completed by laser welding technology. It involves titanium, stainless steel, nickel titanium alloy and cobalt chromium alloy. The research and use of the laser welding process has made it possible to connect two very small parts, which is why laser welding is becoming more and more widely used in medical devices. In addition, plastic materials are now more and more widely used in the field of medical devices. Laser welding, as one of the new plastic production and processing processes, is also widely used in the industry due to its advantages of non-polluting, non-contact, seamless connection. attention.

As a new processing technology, laser technology has become more and more widely used in the medical industry, and gradually makes medical devices more prone to miniaturization, simplicity and comfort. It is believed that through good research and advanced laser technology, it will be more secure in the medical field from equipment processing to anti-counterfeiting packaging.