The packaging industry is an independent, complete and complete industrial system with paper packaging, plastic packaging, metal packaging and glass packaging. The rapid development of the packaging industry not only basically meets the needs of consumption and commodities, but also plays an important role in protecting commodities, facilitating logistics, promoting sales and serving consumption. Metal packaging has excellent barrier properties and comprehensive protection properties. It has good mechanical properties and processability, good surface decoration and various shapes. It is widely used in food, beverage, chemical, pharmaceutical and cosmetic packaging. Metal packaging can be recycled, green and environmentally friendly, and is also the development direction of the circular economy.

| Packing type | Main up industry | Major downstream industry | Major product types |

| Paper packaging | Paper, ink, machinery | equipment Electronics, food, tobacco, food and beverage, medicine etc. | Color box (including boutique box), carton, brochure, aseptic composite paper packaging, paper bag etc. |

| Plastic packaging | Chemical raw materials machinery | Food, medicine, clothing, daily chemical products Hose products etc. | injection products, composite high barrier packaging materials etc. |

| Metal packaging | Metal products, coatings, inks, machinery | Food, beverages, chemicals, pharmaceuticals, cosmetics, arms, etc. | cans (including two-piece cans, three-piece cans), aerosol cans, food cans and various types of caps etc. |

| Glass packaging | Minerals, chemical raw materials, fuels, machinery and equipment | food, beverages, wine, cosmetics, medicine, etc. | Various bottles |

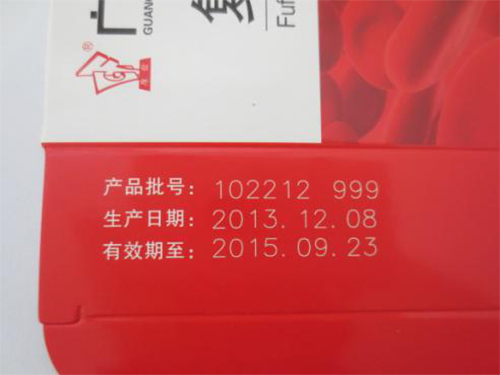

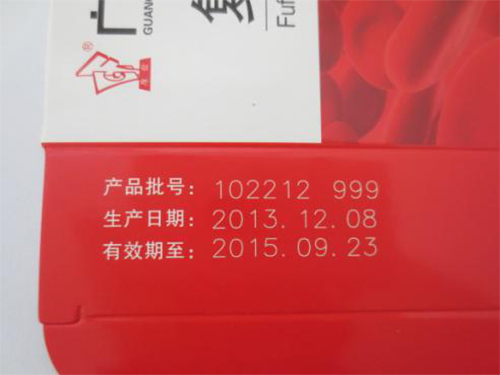

Encoding and marking the production date on various packaging materials is a necessary step, but the problems caused by the traditional ink coding method, such as ambiguous information and information tampering, are unnecessary. With the development of laser technology, the laser can perfectly solve the shortcomings of the pollution information brought by the traditional ink coding.

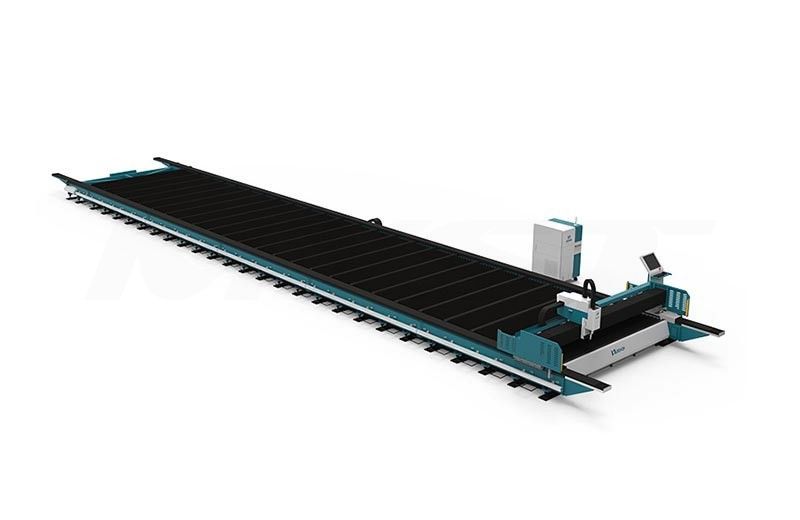

Whether it's paper packaging, metal packaging, plastic packaging or glass packaging, we can use laser marking machine for excellent marking. According to your packaging materials and packaging marking requirements, we have a complete set of solutions.

Paper packaging or soft plastic: For the paper packaging needs to distinguish the type and thickness of the paper and your requirements for the marking accuracy of the packaging, for some packaging UV laser marking machine with relatively thin thickness requirements is a good The choice of soft plastics generally chooses the UV laser marking machine. It is a good choice for some hard paper packaging laser laser marking machine Co2 laser marking machine with less thickness and less precision.

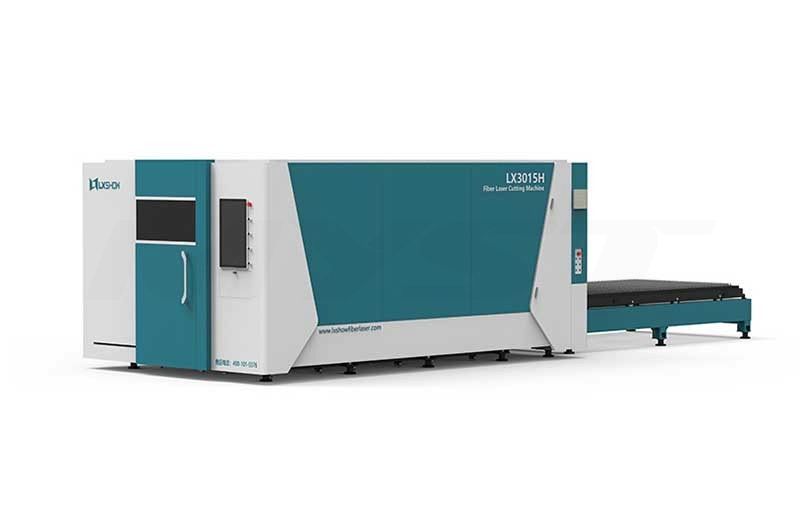

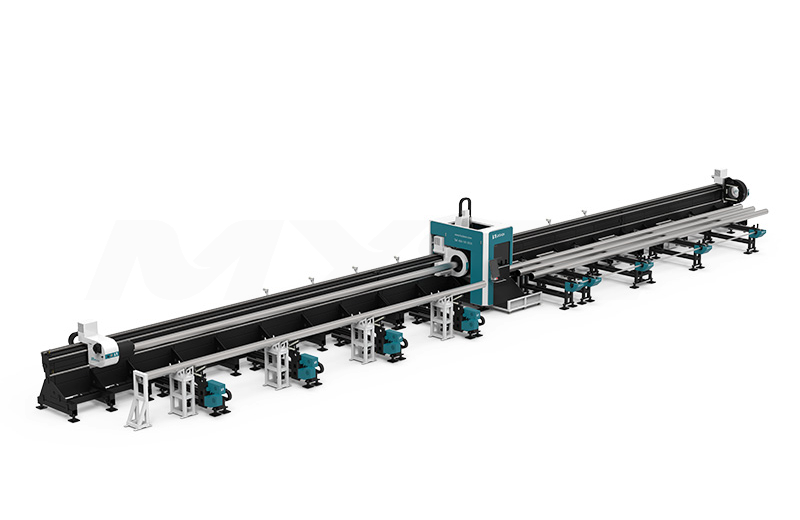

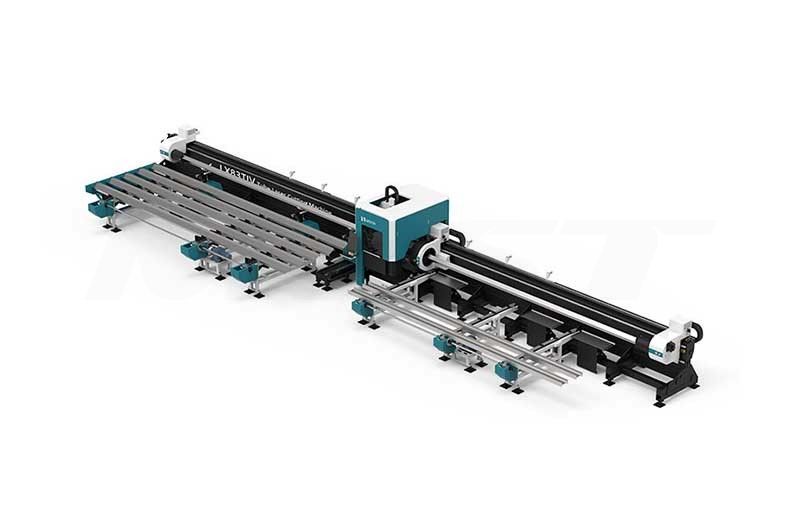

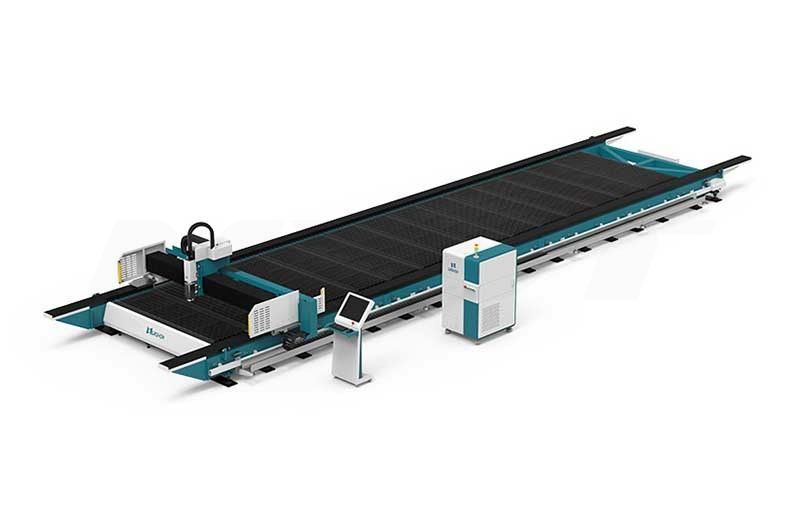

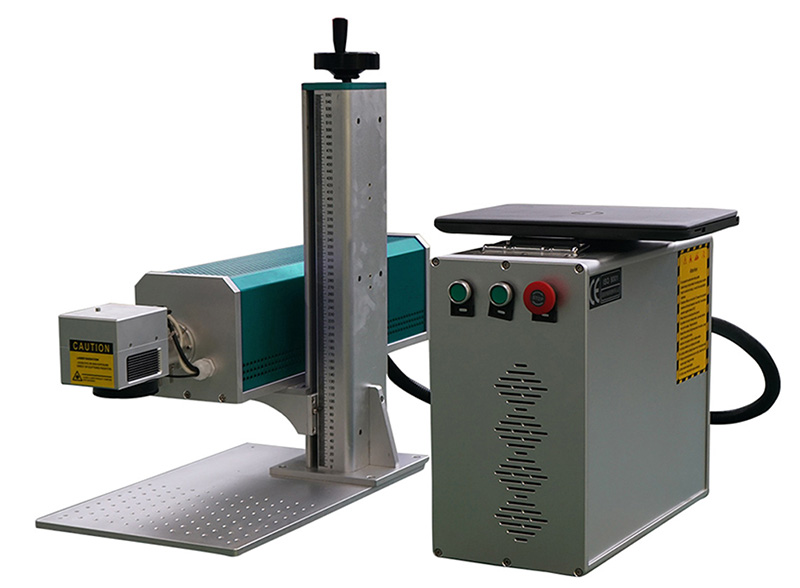

Metal packaging or hard plastic: You can choose fiber laser marking machine or UV laser marking machine, but they still have some differences in marking effect and precision. Ultraviolet laser marking is more precise than fiber laser marking. For some food and medical packaging, UV packaging marking is a good choice, but for some industries that do not require high precision, you can choose a fiber laser marking with good price.

Glass packaging: If you are glass packaging, the marking machine can be selected by Co2 laser marking machine or UV laser marking machine. The wavelength of Co2 laser marking machine is 10600nm. The marking accuracy of natural light source is not as good as that of UV laser marking machine. However, there is a very big advantage in price and price. It is a good choice for some glass packaging co2 that is not too high precision.

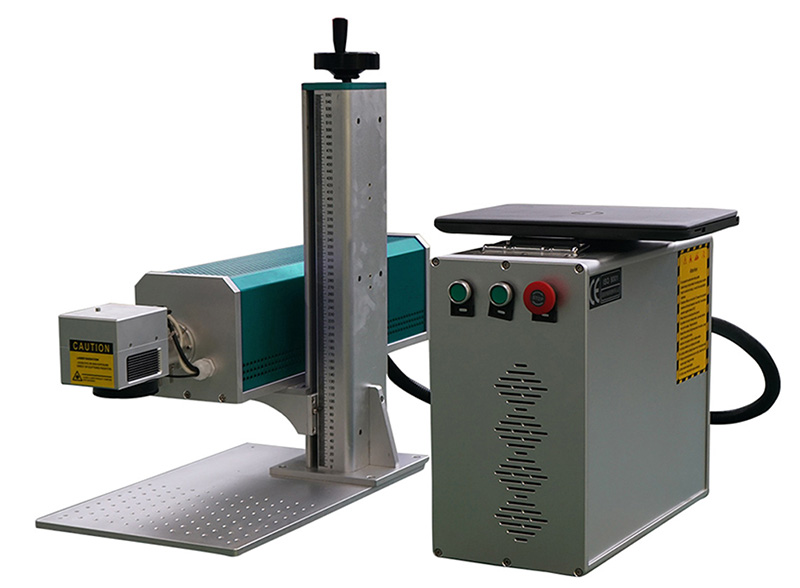

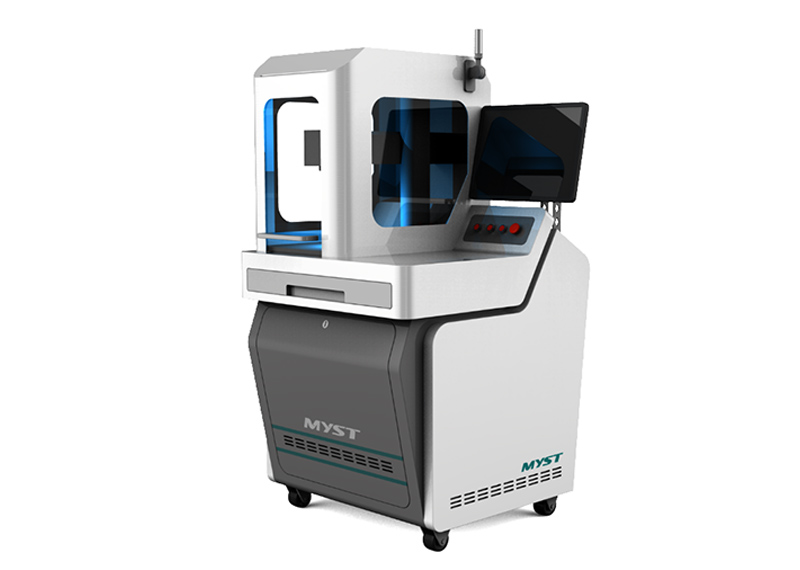

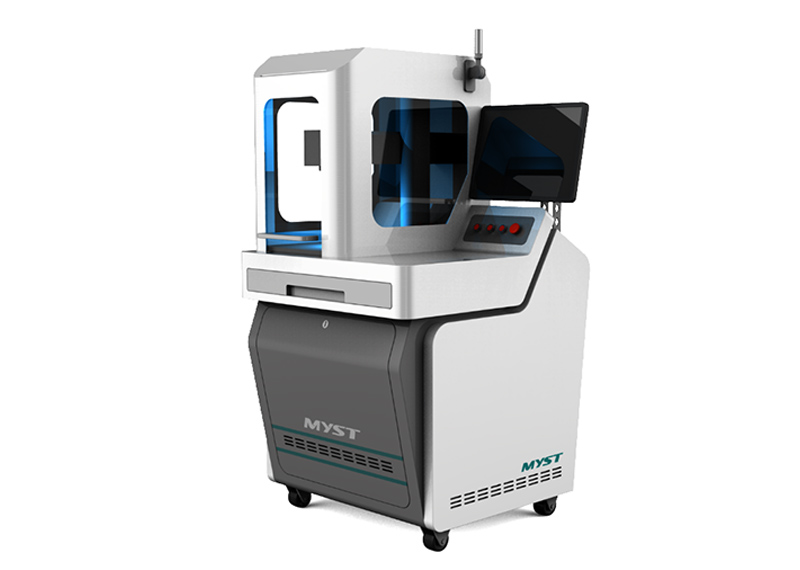

The fiber laser marking machine and the ultraviolet laser marking machine are simple in appearance. The non-professionals are difficult to distinguish as shown in the following figure. The main difference is that the ultraviolet wavelength of 355 nm belongs to the cold light source. The marking accuracy is very high by destroying the molecular chemical bond of the material, but this ultraviolet laser is also very expensive relative to the fiber generator. Co2 marking machine wavelength 10600nm belongs to the hot processing precision is not as good as fiber and UV processing accuracy, but has a good effect on wood and glass material marking.

Co2 Laser Marking machine

Fiber Laser Marking machine

UV Laser marking machine