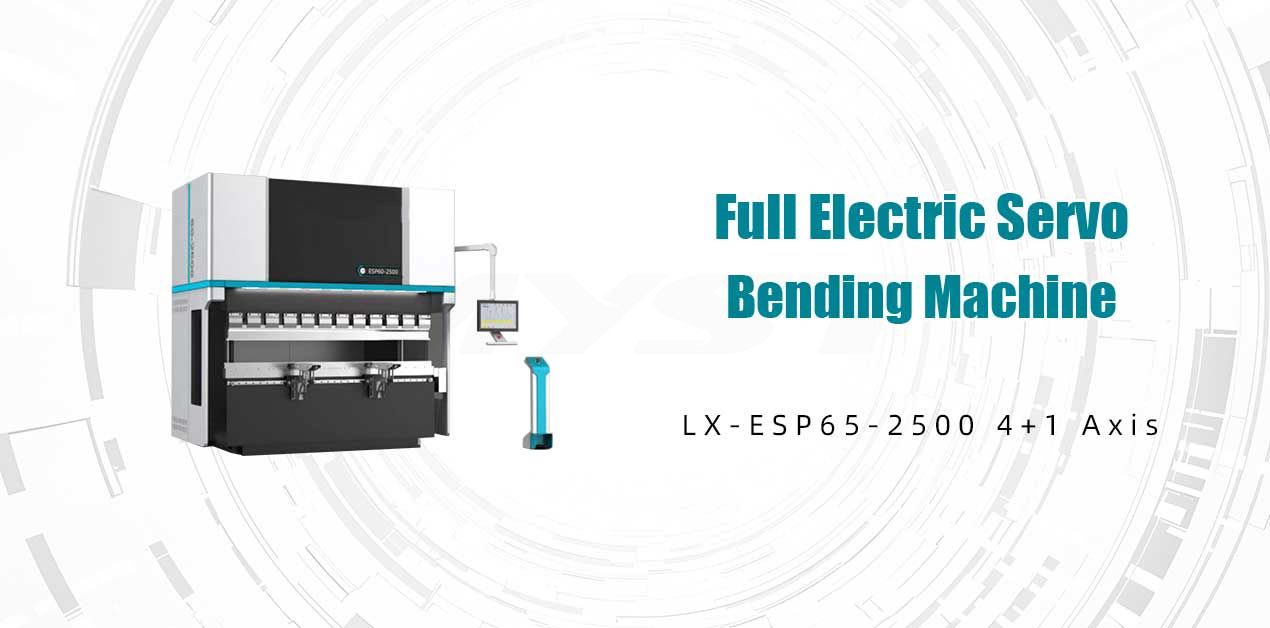

2025 LXSHOW Latest LX-ESP65-2500 4+1 Axis Full Electric Servo Bending Machine

Dimension (L*W*H)mm:2950mm*1600mm*2700mm

Weight :6500KG

Brand:LXSHOW

Payment:Alibaba Trade Assurance, T/T, Western Union, L/C

After service :3 years

Machine Features

1. High bending efficiency and high precision. When bending plates of different thicknesses, a variety of upper and lower molds can be used to bend workpieces of various shapes to meet customer needs.

2. The frame adopts a steel plate welding structure, which is heat-treated and annealed to eliminate internal stress, with high strength and strong rigidity.

3. The all-electric servo integrated system has a simple and practical structure and is green and environmentally friendly.

4. It adopts Taiwan Hiwin's left and right symmetrical double screws, which have stable and reliable performance and precise bending angles.

5. The upper mold is equipped with a quick clamping middle plate with an inclined wedge-type fine-tuning compensation mechanism to ensure excellent bending accuracy.

6. This product adopts Japanese technology, with reliable performance, beautiful appearance, low failure rate and low maintenance cost.

CNC operating system

A. Full closed loop control.

B.System hardware:

Power supply is 24V,15W

CPU low-power consumption,1.0 GHz Intel processor

Full color LCD capacitive touch screen (15 inch TFT)

Ram 4 GB

USB/CAN adapter, IM baud rate, high-speed serial connection

USB 2.0*4, USB3.0*1

Network adapter 1GB Ethernet (RJ45 port)

C.System advantages:

The new generation of controller, the operation interface is friendly, simple and easy to use

Support large arc function

Support Angle input, input is out

Internet of Things Support

Support for external standard USB camera connection monitoring

Powerful diagnostic function and curve detection function

Advanced Y-axis control algorithm can control the closed-loop system

All-electric servo control system

Adopt all-electric servo pump control system, energy saving and environmental protection, full closed-loop control, the same design concept as Japanese bending machines.

Machine frame processing

1、The frame is welded by the left and right side panels, lower panels, with strength and rigidity.

2、After strict heat treatment to eliminate stress annealing welding internal stress,so the machine bed has high precision and good stability.

3、The production process of the frame is all operated by the company itself,which can strictly control the quality.

Bending mold

1、Upper and lower tooling can be installed with multiple short molds splicing or the whole length mold installation, with high precision, good interchangeability, easy assembly and disassembly.

2、It is completely universal and interchangeable with the molds used in the bending machine produced by AMADA company.

Back barrier Back gauge

The standard configuration is four axes (X, Y1, Y2, R) and is equipped with a compensation axis(W).

Wear-resistant Quick Clamp

The inner side of the CNC quick fixture is equipped with wear-resistant rubber strips, which are easy to clamp when installing the bending machine mold, without loosening, and do not drop the tool, which greatly shortens the adjustment time for clamping the upper mold.

Main motor

Servo motors are high quality, innovative and efficient.

X axis Linear Rails and Ball screw transmission

1. The adjustment of the back gauge is driven by a servo motor.

2. The rear gauge screw is positioned by a precision ball screw and supported by a linear guide to guarantee running precision.

Foot pedal switch

1. Improved convenience and efficiency of operation: The operator can control the start, stop or jog operation of the machine by foot, freeing his hands and allowing him to focus on positioning, supporting and adjusting the workpiece.

2. Industrial-grade design: The foot switch of the bending machine usually adopts a design with high mechanical strength and current resistance, which can adapt to harsh industrial environments and is durable.

3. Easy to maintain: A well-designed foot switch, such as modular components, can simplify maintenance and replacement and reduce maintenance costs.