Pure Electric Bending Machine

The pure electric servo bending machine does not use hydraulic oil, and there is no trouble of replacing hydraulic oil and hydraulic components, and there is no replacement, replacement process and daily hydraulic oil leakage of the system, and there is no waste oil treatment and pollution.

China High Quality ET15

1. Reliable performance

The CNC system ET 15 adopts a high-end CNC system development platform and advanced special algorithms for sheet metal bending and motion control algorithms. The main boards all use industrial-grade chips. The CNC system has passed EMC electromagnetic compatibility verification and high and low temperature environment adaptability testing.

2. High speed and high precision control

The numerical control system adopts high-speed acceleration and deceleration algorithms and trajectory look-ahead algorithms. Before bending, the numerical control system performs overall planning of the movement trajectory according to the bending speed and vector characteristics, and ensures good bending accuracy while accelerating and decelerating at high speed. And soft sports characteristics, so that high speed and high precision are effectively integrated!

3. Energy saving and environmental protection

Green and environmental protection: no need to use and replace hydraulic oil, which terminates the pollution of waste hydraulic oil to the environment.

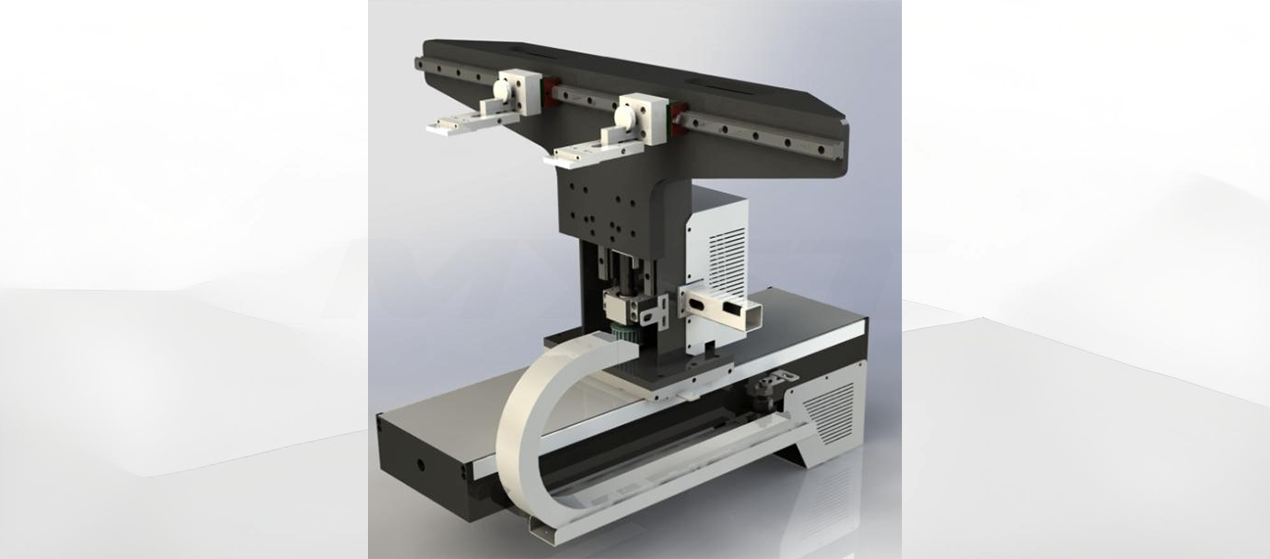

Back Barrier Back Gauge

The standard configuration is two-axis (X, R) CNC floor-standing back gauge, and two-axis (X, R), four-axis (X, R, Z1, Z2), six-axis (X1, X2) can be selected according to different needs of customers , R1, R2, Z1, Z2,)

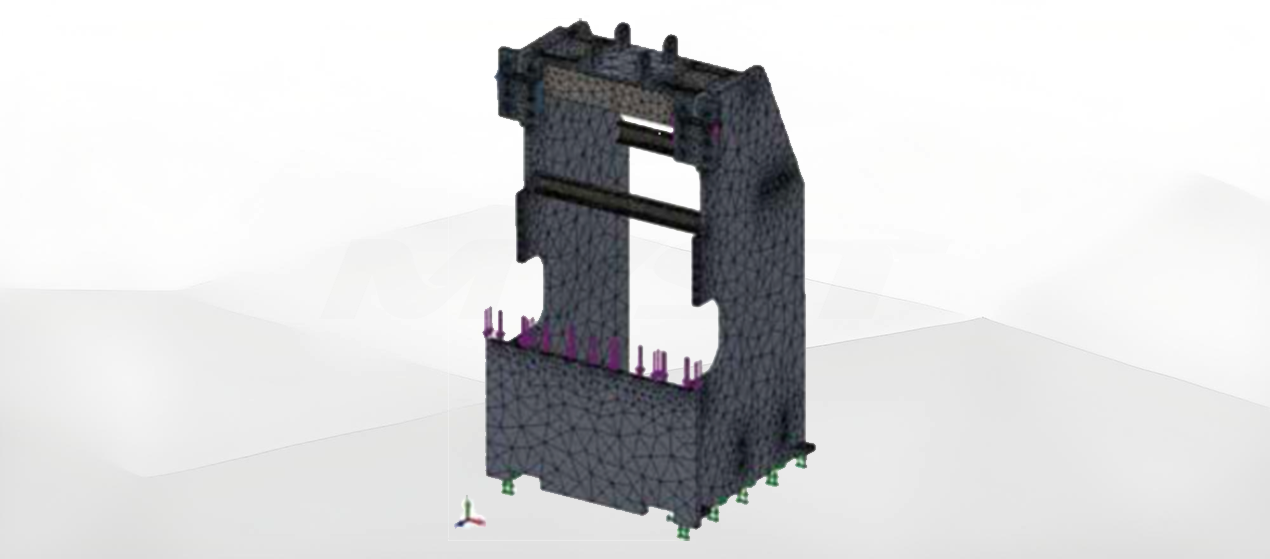

Finite Element Analysis High Rigidity Design

The key mechanical parts of the machine tool adopt finite element analysis for deformation and safety factor to ensure the overall high rigidity requirements and long-term reliability of the machine tool

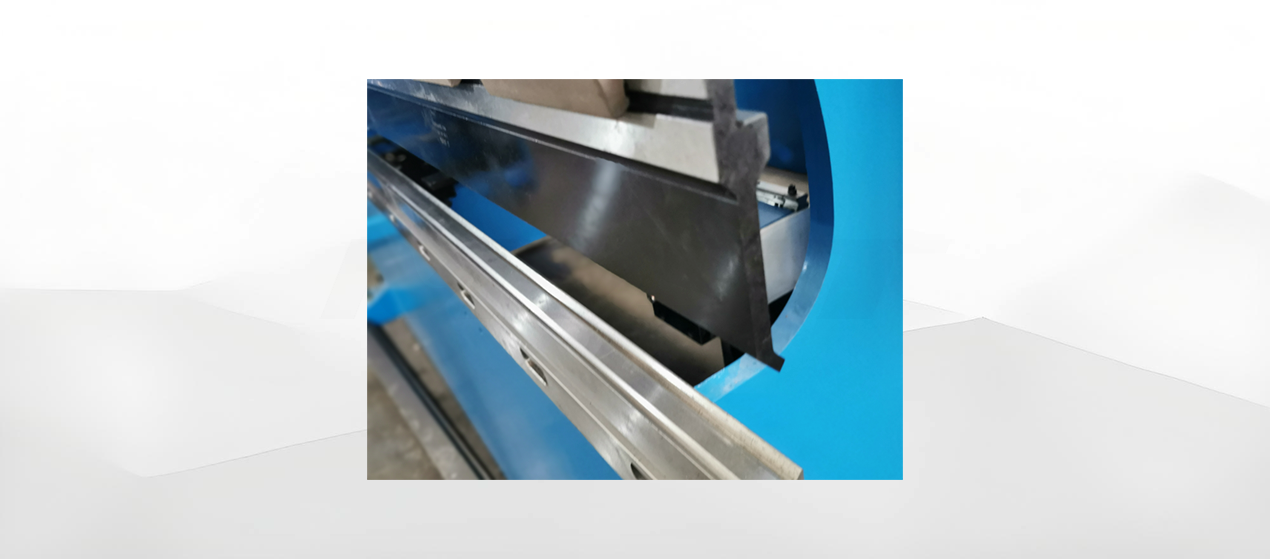

Bending mold

1. The upper die adopts heavy-duty clamping T-slot.

2. The upper and lower molds adopt segmented short molds, and the length required for splicing has high precision and good interchangeability, and is easy to disassemble. The connecting part is equipped with a compensation mechanism to compensate the deflection of the worktable and the slider when bending the sheet to ensure high working accuracy.

3. The lower mold is processed into different "V"-shaped grooves for easy selection by the operator, and it is equipped with a lower mold turning mechanism. Just put the lifting chain on the slider lug and the lower mold lug, loosen the top mold to lift The slider can rotate the lower die to select the required "V" groove position surface.

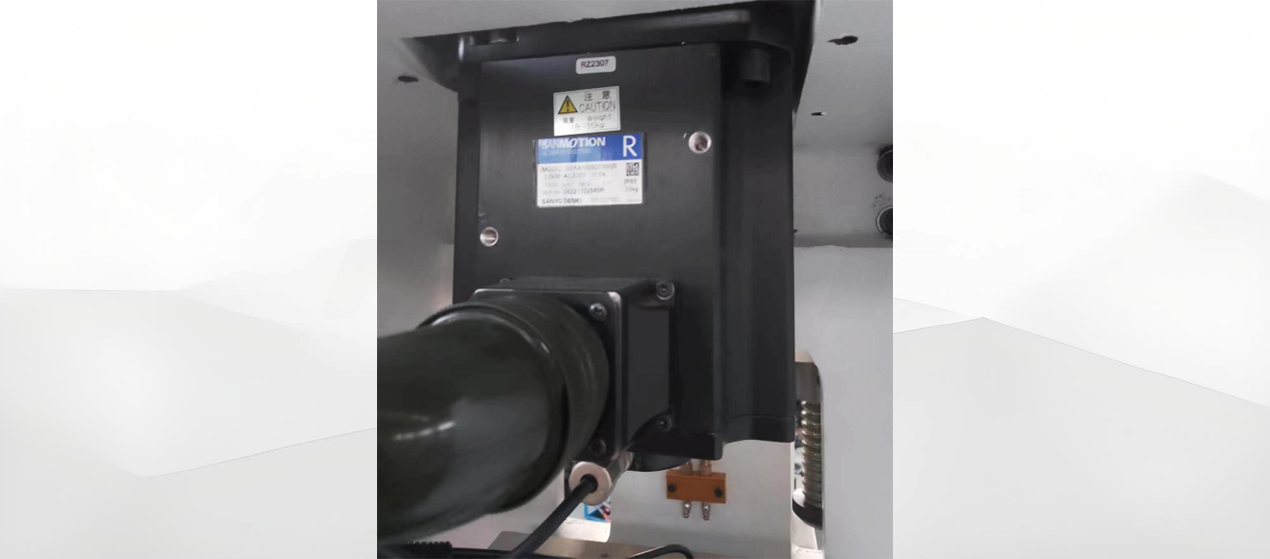

Main motor

1.Servo motors are high quality, innovative and efficient.

2.The motor family incorporates more than 150 years of Siemens experience and is an important element of Siemens' Digital Enterprise solutions.

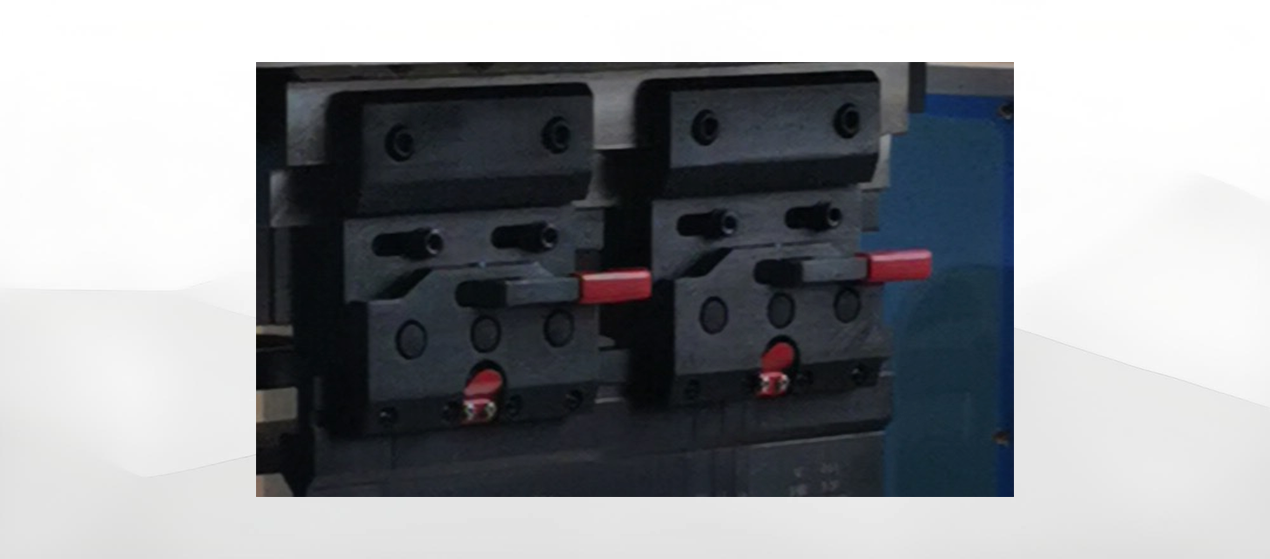

Wear-resistant Quick Clamp

1.The inner side of the CNC quick fixture is equipped with wear-resistant rubber strips, which are easy to clamp when installing the bending machine mold, without loosening, and do not drop the tool, which greatly shortens the adjustment time for clamping the upper mold.