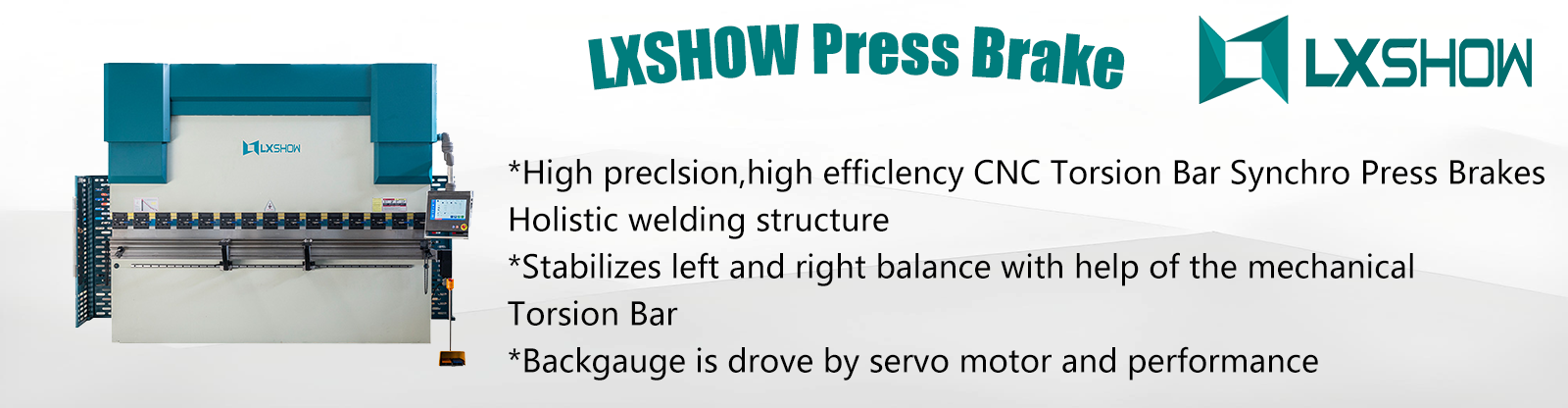

WE67K CNC Electric Hydraulic Press Brake Bending Machine

High preclsion,high efficlency CNC Torsion Bar Synchro Press Brakes

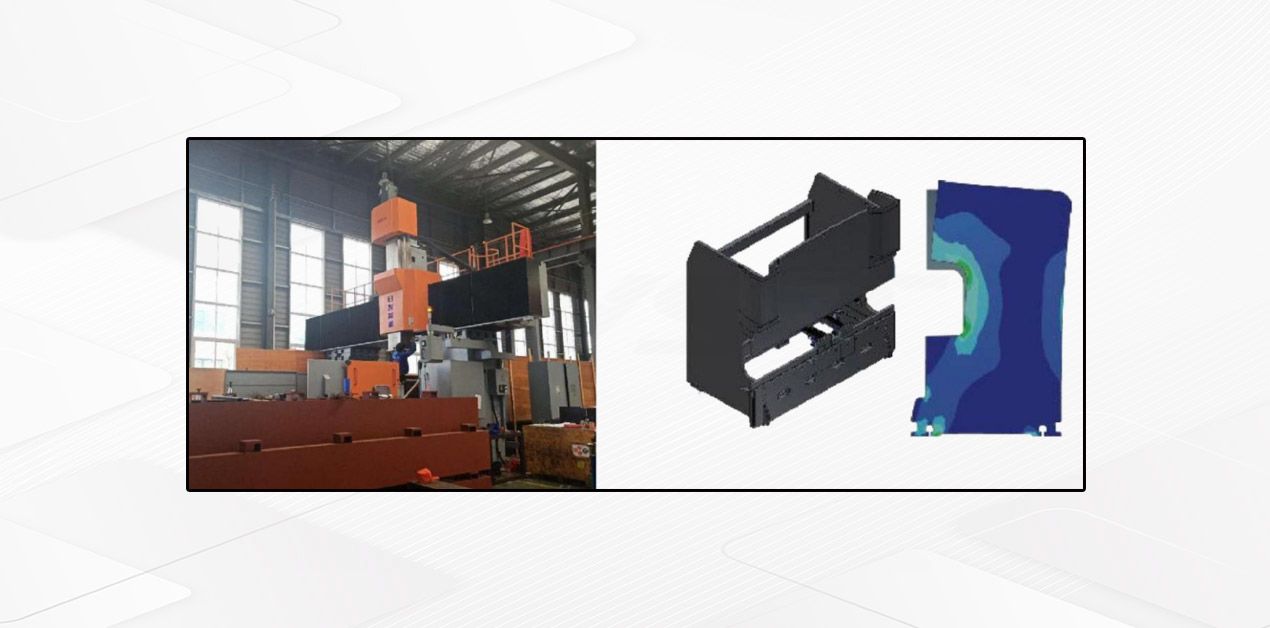

Holistic welding structure

Stabilizes left and right balance with help of the mechanical Torsion Bar

Backgauge is drove by servo motor and performance

Ball screw and Hinear gulde

Features

•Complete steel-welded structure, with sufficient strength and rigidity;

•Hydraulic down-stroke structure, reliable and smooth;

•Mechanical stop unit, synchronous torque, and high precision;

•The backgauge adopts the backgauge mechanism of the T-type screw with smooth rod, which is driven by a motor;

•Upper tool with tension compensating mechanism, In order to guarantee high precision of bending;

CNC System

1. Support switching between angle programming and depth programming

2. Support mold library product library settings

3. The opening height can be set freely for each working step

4. The shift point position can be freely controlled

5. Standard Y1, Y2, R and other multi-axis expansion

6. Support mechanical compensation table control!

7. Support large arc automatic generation program!

8. Support top dead center, bottom dead center, loose foot, delay and other step-changing options, effectively improving processing efficiency

9. Support electromagnet simple bridge

10. Support the function of fully automatic pneumatic dragging bridge

11. Support automatic bending, realize unmanned bending control, and support automatic bending of up to 25 working steps

12. Support valve group configuration function, fast down, slow down, return, unloading action and valve action time control

13.200 product libraries with 25 working steps, each product library name can be customized in Chinese and English, and the large arc supports 99 working steps

Upper Tool Fast Clamp

·Upper tool clamping device is fast clamp

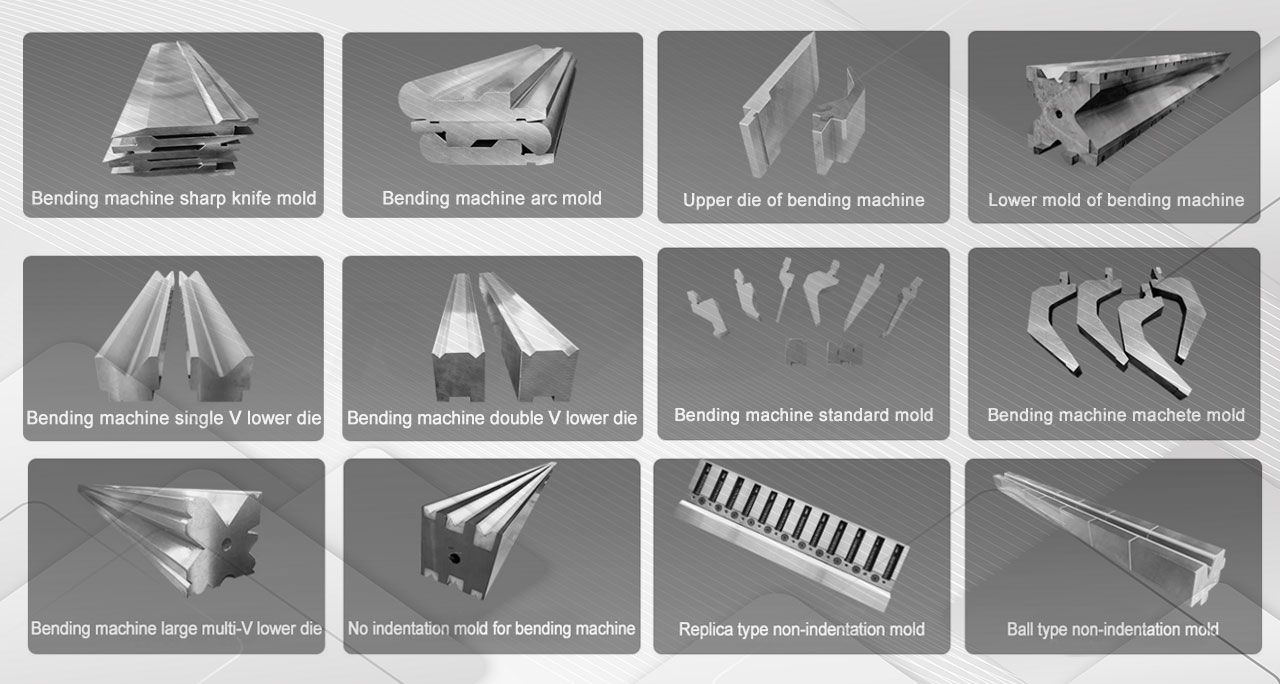

Multi-V Bottom Die Clamping(option)

·Multi-V bottom die with different openings

Backgauge: Ball screw/liner guide are high precision

Front Support

·Aluminium alloy material platform ,attractive appearance,

And decrease scratch of workpicec.

Crowning Compensation for Worktable

· A convex wedge consists of a set of convex oblique wedges with a beveled surface. Each protruding wedge is designed by finite element analysis according to the deflection curve of the slide and worktable.

·The CNC controller system calculates the required compensation amount based on the load force. This force causes deflection and deformation of the vertical plates of the slide and table. And automatically control the relative movement of the convex wedge, so as to effectively compensate for the deflection deformation caused by the slider and the table riser, and obtain the ideal bending workpiece.

Lasersafe Safety Guard(Optional)

·Lasersafe PSC-OHS safety guard, communication between CNC controller and safety control module

· Dual beam from protection are point below 4mm below the tip of upper tool,to protect operator`s fingers;three regions(front,middle and real) of leaser can be flexibly closed,ensure complex box bending processing ;mute point is 6mm,to realize efficient and safe production.

Mechanical Servo Bending Help(Optional)

· When mark bending support plate can realize the function of turning over following.following angle and speed are calculated and controlled by CNC controller,move along linear guide left and right.

· Adjust the height up and down by hand, front and rear can also be adjust manually to suit for different bottom die openning

·Support platform can be brush or stainless steel tube ,according to workpiece size,two supports linkage movement or seperate movement can be chosed.

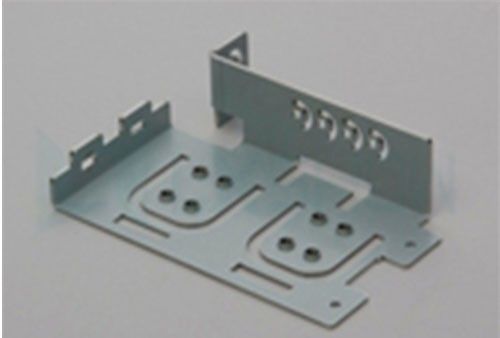

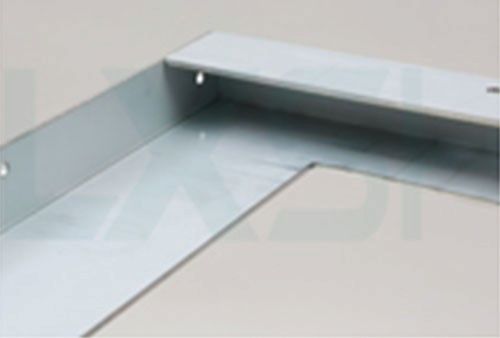

CNC Electric Hydraulic Press Brake Bending Machine Application

CNC press brake bending machines can be used to shape metal sheets into different shapes in various sizes. It can bend non-ferrous metal, ferrous metal sheet, suitable for various industries requiring metal processing, such as decoration manufacturing, automobile and ship manufacturing, aerospace manufacturing, etc.

FAQ:

Q: If we are interested in your machine, how do we choose?

1. What main job you do with the machine? We can make different molds according to your different needs

2. What is your request max working area? __mm* __mm?

3. What's your material thickness & length?

4. What material you want to bending?

Please tell us, then we can recommend the suitable machine to you.

Q: What are the differences between the three types of machines? Which one should I choose?

We have 3 models bending machine for your choice.

1 Electro Hydraulic bending machines

2 efficient bending machines

3 simple bending machine.

The work efficiency is 1>2 >3. also the price is a 1>2>3.

if you can’t confirm, We will quote 3 kinds, then you can choose according to your budget.

Q: How about warranty?

A: We support 3 years warranty,when you have any questions, you cancontact us anytime.

Q: How about your after-sales service?

A: We have a 24-hour professional after-sales service team, which can provide online and offline after-sales service, and we can provide door-to-door service if you need it.