In recent years, the global automotive market demand is increasing day by day, and the automotive intelligentization process is also advancing. Therefore, the replacement of the automobile manufacturing industry needs more and more advanced manufacturing processes to support it. Among them, the laser process is one of the most ideal and current manufacturing requirements, and the combination of advanced laser manufacturing technology and automobile production is the trend of the times.

While promoting the development of the automotive industry, lasers have also brought more opportunities to manufacturers. Compared to traditional manufacturing techniques, laser technology is more flexible and efficient, and easy to automate, which is a good fit for the core needs of automotive manufacturing. Throughout the automotive industry, laser technology has matured in the fields of cutting, welding and marking.

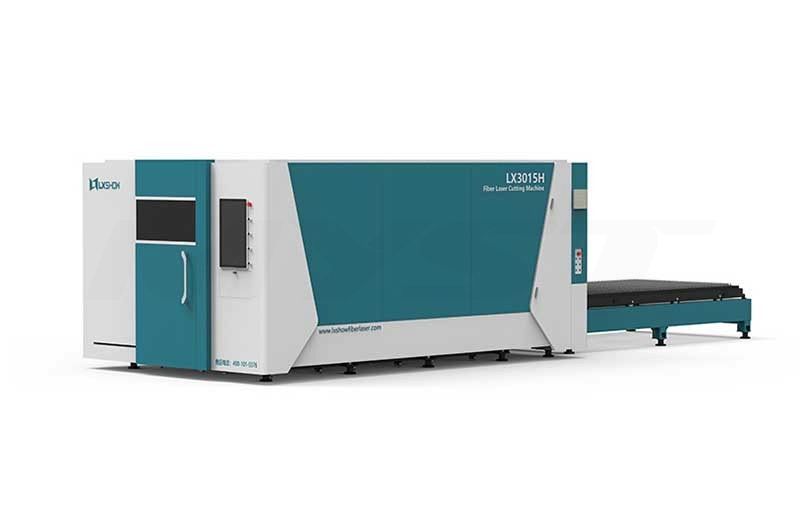

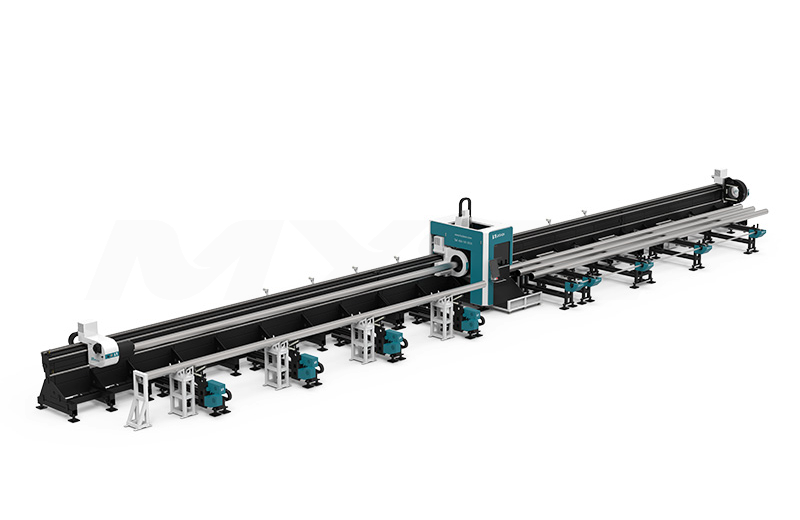

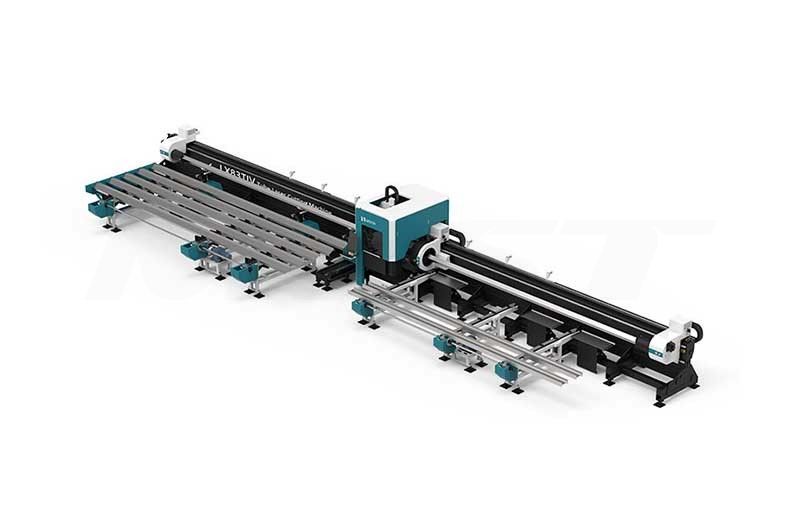

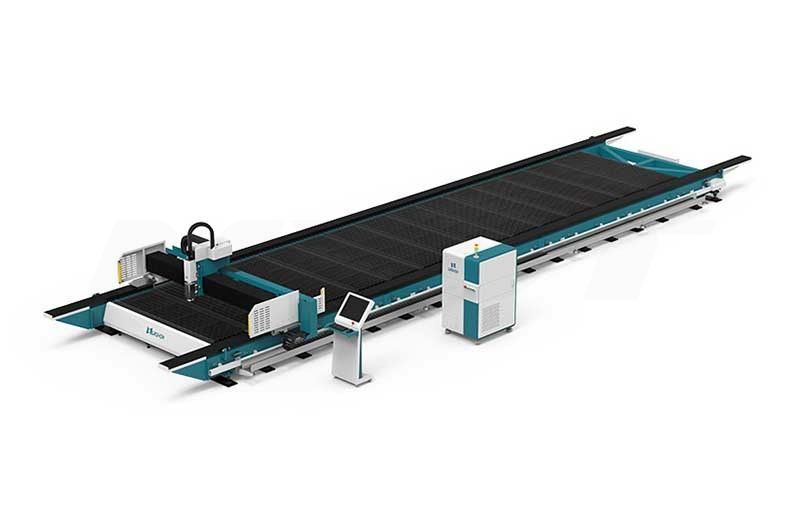

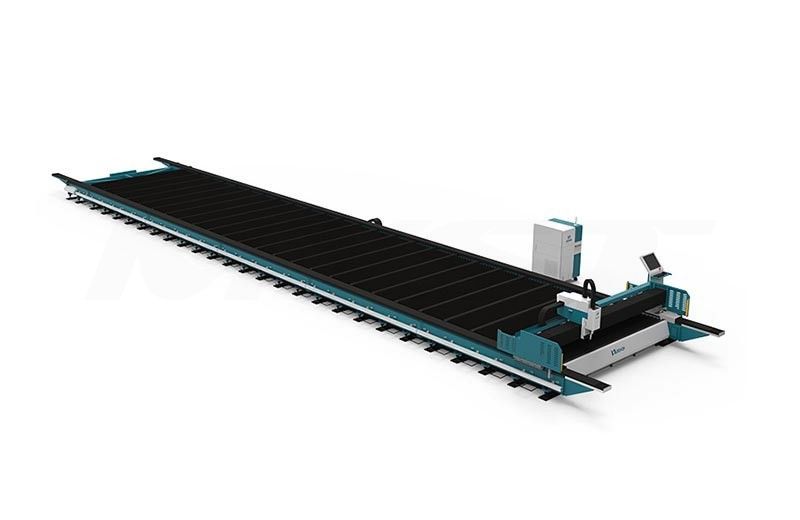

1. Laser cutting for automotive component manufacturing

Laser cutting is suitable for difficult-to-machine metal materials such as aluminum, aluminum alloy, carbon steel, stainless steel, etc. Its processing speed is fast, the cutting is efficient and flexible, and the cutting edge quality is high. It perfectly fits the auto parts and materials processing including multi-metal, and Today, environmental protection is increasingly promoted, laser cutting uses non-contact processing, to ensure that no consumables, but also no pollutants, but also in line with the development of the industry. And with the continuous improvement of the process, automotive interiors and even airbags made of composite materials can be molded in one time using a laser process. A "light" dual use has increasingly become the standard for the development of the industry.

2. Laser welding for assembly of automotive components

Whether it's the welding of car bodies, pipes, or the welding of automotive batteries and instrument panel plastics, lasers have unique welding accuracy and speed. Laser welding is a highly efficient precision welding method that uses a high energy density laser beam as a heat source. Using the high temperature of the laser, the molecular structure in the two steel plates is disturbed, and the molecules are rearranged so that the molecules in the two steel plates are dissolved into one. Since continuous laser welding does not require the use of sheet edge stack welding as in the conventional spot welding process, it is often used by automobile manufacturers for welding between the roof and the body, and has the advantages of good appearance, sound insulation and good sealing. In laser applications in automotive manufacturing processes, automotive body-in-white welding is the most difficult, and it requires not only the precise precision of the fixture to achieve the best possible welding. And as the demand continues to increase, the automotive manufacturing line has also put forward new requirements: seamless integration of the production line. The stable low heat input of laser welding is the quality assurance during the welding process, which effectively prevents the occurrence of problems such as body deformation, flaw welds and uneven welding. On the other hand, the effective welding speed and the easy integration of the automation device also provide seamless support for the production line, and a "line" molding guarantee.

3. Laser marking for automotive component identification

Although the automobile industry is already moving toward a higher end and a more perfect direction, we still can't think of all the factors in the ground. So far we still hear news about the car recall, and in the process of recall, the car and The unique identity of the components has become the basis for the traceability of product quality. First, compared with ordinary adhesive paper and inkjet marking, the marking left by the laser marking machine on the body or the component itself has the characteristics of permanentness and high contrast, which is more popular among people. Second, less independent mass production, and more integrated production lines, to meet the needs of different parts. Third, the use of laser bar codes and two-dimensional codes makes laser markings no longer just a simple sign, but rather a new kind of information carrier. It is easier to realize identity establishment in vehicle or parts recall. This has important special significance for the current automotive industry.

Throughout the entire automotive manufacturing field, laser technology filaments infiltrate, but they are important. On the basis of already meeting the various needs of the current industry, it will certainly set off more new enthusiasm and become a new enthusiasm for the industry.