The rapid development of science and technology continues to drive the transformation and upgrading of the laser cutting market. The emergence of fiber laser cutter meets the needs of modern enterprise sheet metal processing to the greatest extent. Sheet metal cutting machine becomes the most popular metal cutting equipment in the sheet metal processing market. Its use makes sheet metal processing truly enter the era of automation, which greatly improves the efficiency of sheet metal processing and injects strong impetus into the development of the enterprise. At the same time, the materials processed by the cnc cutting machine can better meet market demand, become more competitive in the market, and can bring greater economic benefits to enterprises. This is also the market effect that enterprises continue to pursue in today's rapid development of commodity economy.

Laser cutting machine for steel

Fiber laser cutting means that a high-energy laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, while the high-pressure gas blows away the molten or vaporized metal. As the relative position of the laser beam and the workpiece moves, the material will eventually form a slit to achieve the purpose of cutting.

With the continuous transformation and upgrading of cutting technology, the problems of slow perforation speed, small cutting thickness, non-smooth cutting section, and unstable production of the whole board faced by traditional cutting processes have been solved. Long-term stable operation of the equipment has been achieved, and the economic benefits of the manufacturer have been greatly improved. The research and development of laser cutting technology is designed to improve the quality of product processing and meet the needs of sheet metal processing in various industries. According to the differences in the processing width, thickness, and processing complexity of the sheet, it forms common edge cutting, high power cutting, and bright Leading processing technologies such as face cutting and high-pressure air cutting have enabled metal cutting machines to occupy a leading position in the sheet metal cutting market.

Sample of laser cutting machine

Compared with the traditional cutting process, steel laser cutting has higher cutting quality, faster processing speed, more types of cutting materials, and is not limited by the surface and shape of the workpiece. These characteristics of laser cutter steel have greatly reduced the production cost of manufacturers, which has also become an important reason why steel cutting machines are sought after.

Fiber laser cutting technology is so popular, what economic benefits can a cnc machine metal bring to buyers?

1. The processing cost of the laser cutting of sheet metal is low, there is no contact with the processing material, no pollution to the environment, no consumables, and can effectively reduce the material cost of the manufacturer. Especially in the sheet metal processing industry, it faces a large amount of metal processing needs every day. The cutting without consumables and the finished product after cutting can be used without secondary processing, which is a great boon for manufacturers.

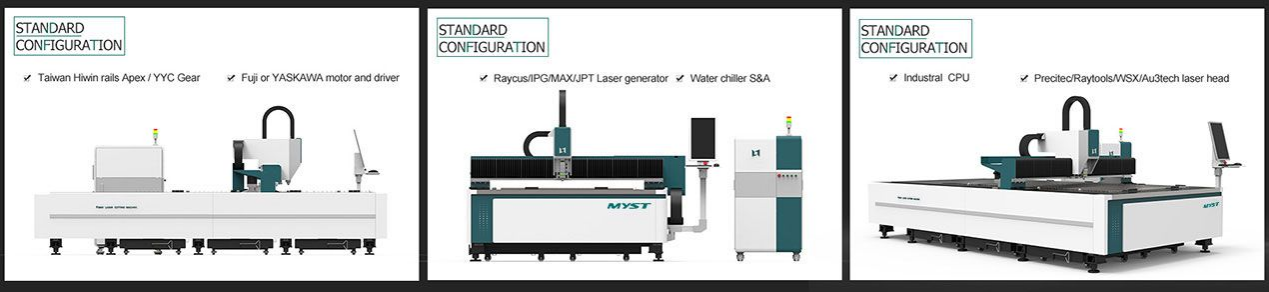

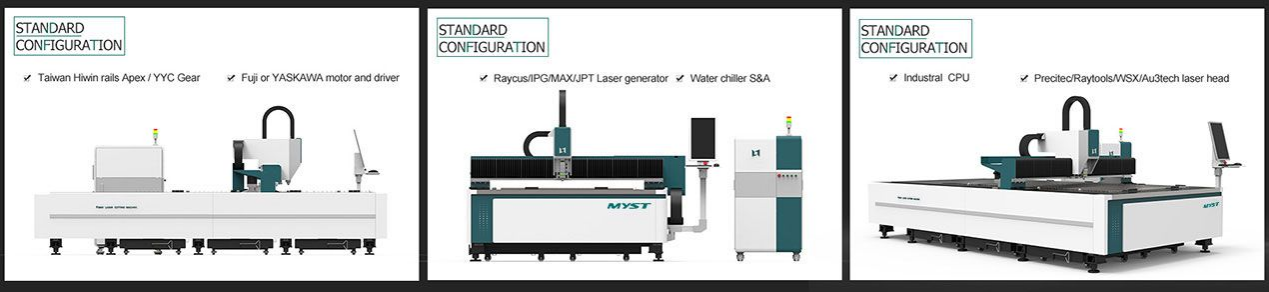

Display of fiber laser cutting machine

Display of fiber laser cutting machine

2. The cutting quality of the laser cutting metal sheet machine is high and the cutting speed is fast. Product quality is the foundation of enterprise production and an important element that affects consumers’ purchasing decisions. The high-quality cutting advantage of iron cutting machine along with the high-speed cutting speed is the only magic weapon for sheet metal manufacturers to improve production efficiency and increase economic value, and it is also the basis for higher competitiveness in the competition of the same industry.

3. The sheet metal laser cutting machine is not limited by the shape of the cut material when cutting. Because laser cutting has the characteristics of flexible processing, three-dimensional cutting can be achieved during cutting, so it is not limited by the shape of the workpiece. For the sheet metal processing manufacturers that needed molds in the past, the laser cutting sheet metal can save the time and cost of mold production, and sheet metal of any shape can be cut on site. In this way, the cycle from R&D to production is greatly shortened, and valuable time is gained for product launch.

cutting machine for metal sheet

4. The laser sheet metal cutter can process more types of materials. It can cut most of the common metals on the market, such as carbon steel and stainless steel. Aluminum and other metals. For high-reflective materials such as aluminum, copper, and zinc, fiber laser cutting machines are currently unable to cut thick plates. This is also the focus of improvement in the subsequent development of sheet metal laser cutters. But don't worry, the laser cutter sheet metalcan be perfectly qualified for the current sheet metal processing needs on the market. Manufacturers only need to purchase a metal sheet laser cutting machine to meet the needs of simultaneous processing of multiple materials, which can save money and improve work efficiency.

fiber laser cutter

The processing cost of the metal sheet laser cutter is low, and the finished product after cutting can be used without secondary processing. The cutting speed is fast, the production cycle is short, and there are many kinds of materials that can be cut, and it is not limited by the shape of the workpiece. These outstanding advantages of fiber laser cutters can bring higher profits to enterprises and enable enterprises to obtain greater economic benefits. Therefore, they are favored by many manufacturers and become the focus of the market. If you have sheet metal processing needs, you are still considering whether to buy a metal sheet cutting machine. After knowing the incomparable advantages of traditional cutting equipment, what are you still hesitating? A metal sheet cutter can meet all your sheet metal processing needs, buy early to enjoy, buy early to make money.

Fiber laser cutting machine factory

In order to adapt to the complex and changeable processing environment and processing requirements, the laser cutting process continues to innovate and reform, and gradually forms a series of complete sheet processing solutions, enabling the sheet cutting machine to operate efficiently and stably in the sheet metal processing industry. MYST LASER as a leader in laser intelligent equipment in China, has 16 years of experience in laser equipment production. It is customer-centric, puts customer interests first, and always upholds the production philosophy of customer first and quality first. Every cutting machine for metal sheet produced by MYST LASER has undergone layers of technical checks and quality inspections, and has an independent and complete after-sales service system to ensure that customers have no worries about purchasing the machine and after-sales. If you want to occupy a place in the sheet metal processing market where the weak and the strong eat, and improve the economic efficiency of the enterprise, you only need to purchase a laser cutter fiber from MYST LASER to meet all your needs.