If you're looking to mark metal, what you need to buy is a fiber laser. If you're looking to mark organic materials like textiles, wood, or cardboard, a CO2 laser is the best choice.

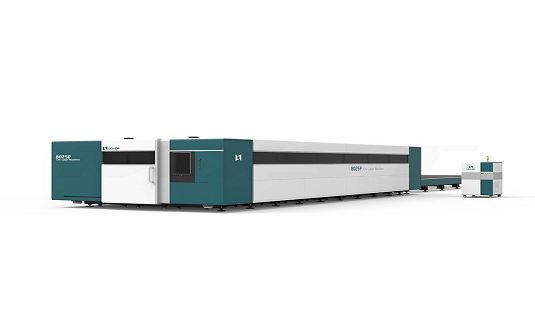

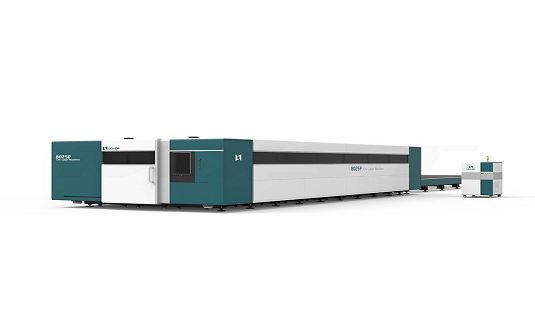

High Power Fiber Laser Cutting Machine

If your application is laser cutting of metals, you'll most likely need a high-power CW (continuous wave) fiber laser. For other materials like plastics and rubber, it can be one or the other.

The main difference that determines the type of materials each laser can process is the wavelength. A fiber laser usually has a wavelength of 1,060 nm while CO2 lasers have wavelengths in the 10,600 nm range. In general, fiber lasers have many advantages over CO2 lasers.

Many people think that fiber lasers can only cut thin materials. CO2 lasers with larger wavelengths can produce cuts in thicker materials. But in recent years, this problem has been solved through technology.

This technology can generate a wider fiber laser beam, thereby creating material separation and material removal space in thick materials. And because the beam width can be switched, the machine can use a narrower beam to process thin materials, so that materials of different sizes can be processed faster on the same fiber laser cutting machine.

The Differences Between Fiber Laser And Co2 Laser

Different power

Since its beam diameter is usually one-third the size of a CO2 beam, the power density of fiber lasers is higher than that of CO2 laser beams. This not only allows the fiber to cut faster but also allows it to pierce faster. This small beam size also enables the fiber to cut complex shapes and leave sharp edges. Because of the large amount of power required to create a CO2 laser, it is less efficient than fiber lasers, and the wall plug efficiency is much lower. Therefore, the large cooler required by the CO2 laser also requires more total power. Given that the wall insertion efficiency of fiber laser resonators exceeds 40%, you not only use less power but also take up less space.

Different wavelength

The wavelength of the fiber laser is 1.06 microns, which is 10% smaller than the wavelength of the CO2 laser beam. Due to the smaller wavelength, the beam produced by the fiber laser is more easily absorbed by the reflective material. The CO2 laser is more likely to be reflected by the surface of these materials. Therefore, the fiber laser cutting machine can cut brass, copper, and other reflective materials. The CO2 laser beam reflected from the material will not only damage the cutting lens of the machine, but also the entire beam path. Using fiber optic cables for the beam path can eliminate this risk.

Fiber Laser Cutting Machine

Maintain

Fiber lasers do not require much attention in terms of maintenance. It is not like a CO2 laser cutting machine that requires mirror cleaning and bellows inspection. As long as it is cooled with clean cold water and the air filter is replaced regularly, the fiber laser itself does not require preventive maintenance.

Specific Applications

Fiber Lasers

Fiber lasers are best suited for high-contrast markings like metal annealing, etching, and engraving. They produce an extremely small focal diameter (resulting in intensity up to 100 times higher than a CO2 system), making them the ideal choice for permanent marking of serial numbers, barcodes, and data matrix on metals. Fiber lasers are widely used for product traceability (direct part marking) and identification applications.

One big plus is fiber lasers are maintenance-free machines, and they have a long service life (our lasers have a minimum of 100,000 operating hours). They are also smaller than CO2 lasers. Plus due to the high electrical efficiency of fiber lasers, they use significantly less power than CO2 lasers, resulting in huge cost savings for cutting applications.

Fiber lasers also have a growing demand for industrial cleaning applications such as removing rust, paint, oxides, and other contaminants.

The cost of a fiber laser system will greatly vary depending on your applications. Industrial fiber lasers systems for demanding environment like we do usually start at $40,000 and can go up to $1,000,000 for high-power laser-cutting machines. The power usually ranging from 20 W to 6,000 W will have the largest impact on price.

CO2 Lasers

CO2 laser marking is ideal for a wide range of non-metallic materials including plastics, textiles, glass, acrylic, wood, and even stone. They are used in pharmaceutical and food packaging as well as the marking of PVC pipes, building materials, mobile communications gadgets, electrical appliances, integrated circuits, and electronic components.

If you need to cut thicker materials, it's best to go with CO2 lasers. CO2 lasers deliver faster initial piercing times, quicker straight-line cutting and a smoother surface finish when cutting materials above 5 mm.

Unfortunately, CO2 lasers use significantly more power than fiber lasers, resulting in a higher cost of operation. For instance, a high-power CO2 laser and chiller will consume roughly 70 kW when operating on maximum power. A similarly powered fiber laser consumes approximately 18 kW.

The cost of CO2 lasers tends to be less than fiber lasers. The price for CO2 laser marking systems usually ranges between $35,000 and $80,000. Again, the power (which usually ranges between 20 W to 150 W) will influence the cost.

Conclusion

Although each laser does have its strengths and distinct use cases, CO2 is an older technology and fiber lasers are gaining market fast as the technology advances. With the speed benefits, almost half of the operating costs and three to four times greater throughput than CO2 lasers, the financial gains that can be got from using fiber lasers can be game changing. We are a Fiber Laser Cutter supplier, please feel free to contact us if you need them.