High power laser cutting machine uses a fiber laser to the output laser beam and focuses on the surface of the workpiece. The area of the workpiece that is irradiated by the ultra-fine focus spot instantly melts and vaporizes. The laser beam is automatically cut by moving the spot irradiation position through the CNC mechanical system. It is a piece of high-tech equipment integrating fiber laser technology, CNC technology, and precision mechanical technology.

At present, the high-power laser cutting machine is suitable for non-contact cutting, hollowing, and perforation processing of various metal plates and metal pipes. It is especially suitable for cutting metal materials such as stainless steel plate, carbon steel plate, galvanized plate, thin aluminum plate, thin copper plate, thin gold plate, and thin silver plate with thickness below 40mm.

Features of high power laser cutting machine

1. High power cutting head in the case of high power continuous operation is the core component to ensure stable cutting, with the following characteristics.

①High power cutting head has a better sealing and cooling more adequate cooling system, a wider range of applications of the focus, and more resistance to high temperatures of the lens.

②The cutting head will have a focal point drift phenomenon when the beam is working for a long time. In order to overcome the focal drift problem, the high-power cutting head adopts a new air circuit design structure and a new structure of nozzle. In order to improve the cutting speed and cutting stability.

2. Multiply the efficiency of cutting medium and thin plates. The thickness of cutting thick plates is increasing.

3. Short perforation time, small thermal focus energy. The starting point is stable, keeping the stability of the follower system. It can ensure to achieve the best cutting effect.

Advantages of high power laser cutting machine

1. High speed

Laser cutting speed is high, the two axes of the processing cutting machine move fast and the acceleration has reached a high level during the operation.

2. High precision

The error between the small holes in the plate during the cutting process is very small.

3. To the direction of thick plate

High-power laser cutting machine power gradually increased, the corresponding cutting of thick plate size has also been increasing.

4. To the direction of large size

Laser cutting technology is also increasing the range of processing size, laser cutting technology has begun to develop in the direction of large size.

5. Intelligent

In accordance with the technical requirements of Industry 4.0, follow the pace of intelligent manufacturing. Adopting accurate graphic recognition technology, simple operation process, convenient human-computer intelligent interaction. Laser and computer control, CNC technology, optical systems, high-precision, and automated positioning devices, etc., combined with automatic material scheduling, cutting process database, remote fault diagnosis, remote control, etc. into one. Meet the needs of high-volume and complex parts processing.

Final words

Enterprises need to consider carefully when choosing high-power laser cutting equipment. In addition to the cutting speed and accuracy, especially to check the stability and consistency of the full power continuous cutting, the machine speed matching ability, the accuracy of the machine control and service life, etc. You can't simply compare price factors as you would when buying a low-power laser cutting machine. High power means high investment, high investment implies high risk. Companies must be aware of the risk when entering this high-return market. We recommend MYST high-power laser cutting machines.

Transmission And Precision

MYST fiber laser cutting machine is equipped with a German Atlanta rack, Japanese Yaskawa motor, and Japan THK Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

Independent Control Cabinet

Dust-proof

All electrical components and laser sources are built-in into the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

Automatic Thermostat

The control cabinet is equipped with an air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

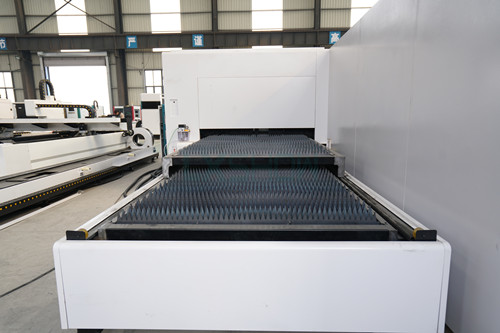

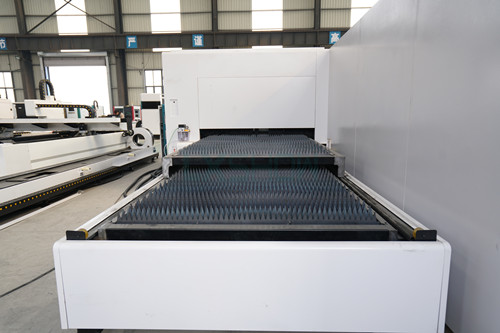

Exchange Table

It adopts an up and down exchange platform;

The converter is responsible for controlling the exchanging motor;

The machine is able to finish the platform exchanging within 15s.

Safety and No Pollution

·With a fully enclosed design;

·The observation window adopts a European CE Standard laser protective glass;

·The smoke produced by cutting can be filtrated inside, it's non-polluting and environmentally friendly.

LXSHOW LASER LX3015PT is a product specially designed for sheet metal laser cutting machines. It has a stronger cutting ability and higher cutting precision. Do you want to know more about it? Here is a product details page that can help you.