Fully Automatic Pipe Bending Machine can bend in 3D

The fully automatic pipe bending machine uses the latest Taiwanese touch screen, which displays all machine functions, messages and program settings in bilingual (Chinese/English).

The working speed of each axis can be set to save working time and increase production. There is a counting function to calculate the number of jobs.

The pipe bending function can make a perfect ellipse even when the pipe is large in diameter or with a small bending radius, and the parameters can also be set to compensate for the rebound value of the pipe bending.

Advantages of fully automatic hydraulic pipe bending machine

Display the machine top view diagram. Simply touch the relevant icon button to operate the specified machine function.

There are multiple modes for automatic or manual operation.

Built-in self-detection inspection system and report function, display all abnormal or error information, indicate the treatment method, and record the latest information for maintenance reference.

Humanized touch screen, easy to operate and easy to set the program, can quickly change the mold device, and use the machine setting in the least time.

The working speed of each axis can be set to save working time and increase production. There is a counting function to calculate the number of jobs.

The bending function can also make a perfect ellipse when the pipe diameter is large or the bending radius is small, and the parameters can also be set to compensate for the rebound value of the bending pipe.

Through program planning, the built-in battery can be stored for 6 months after the power is cut off, and the data and program are also protected by passwords and keys.

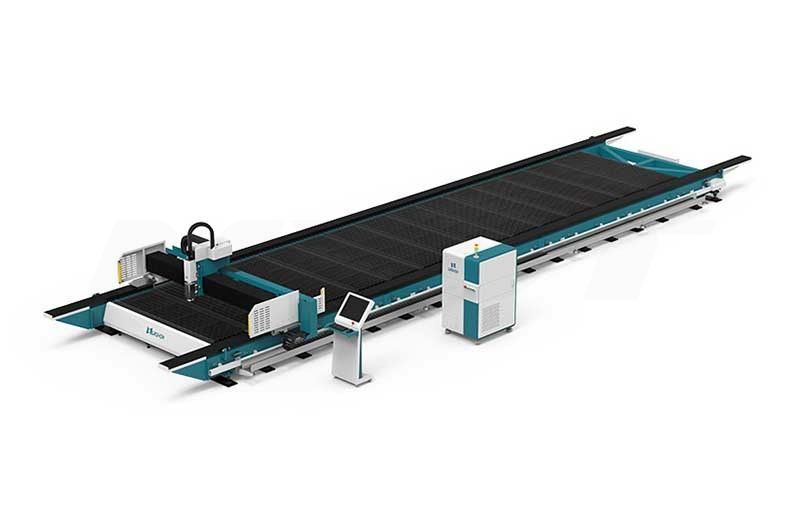

Specially equipped with servo motor fixed length, servo motor controls automatic angle, and can bend multi-angle three-dimensional pipe fittings.

Multi-layer protection device ensures the safety of the operator, and can be operated manually or semi-automatically. Automatic sensor detection and error indication to avoid human damage to the machine or mold.

Perfectly designed and refined machine head, combined with a strong structure, provides the largest bending space to reduce any interference factors.

A variety of special equipment is provided for customers to choose from to make the product more perfect.

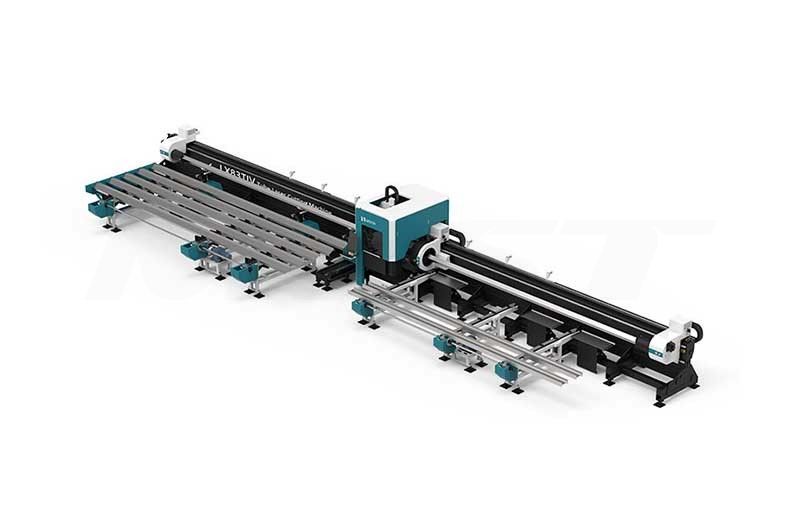

Clamping mechanism

The clamping mechanism of the pipe bending machine is a key component used to fix the pipe and ensure that the pipe will not move or rotate during the bending process.

Oil pump motor

The oil pump motor of the pipe bending machine is the core component that provides power to the hydraulic system.

It is responsible for driving the oil pump and converting mechanical energy into hydraulic energy to achieve precise bending of the pipe.

Mould

The mold of the pipe bending machine is a special tool used to define the bending shape and size of the pipe. It controls the bending radius and

angle by designing the contact surface with the pipe to ensure that the bent pipe meets the predetermined specifications.

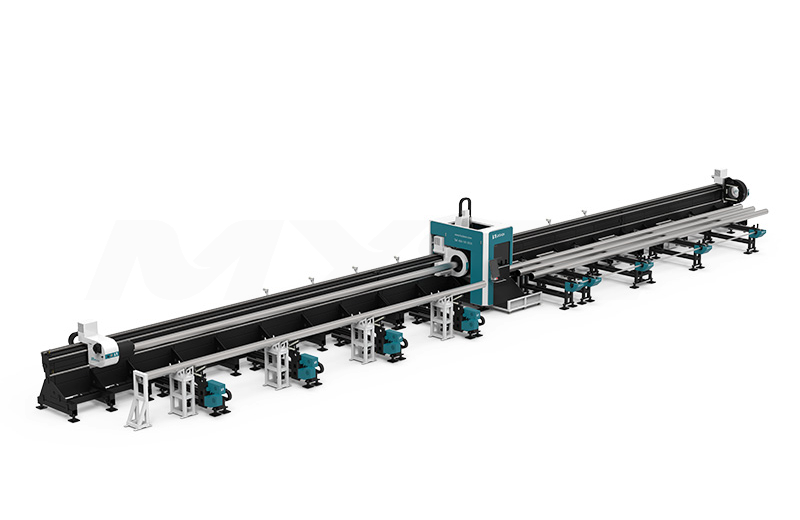

Feeding device

The feeding device of the pipe bending machine is a key component used to transfer the pipe from the feeding device to the bending mechanism.

It clamps the pipe to be processed and pushes the pipe to move along a predetermined path to achieve continuous bending of the pipe.