Professional laser cutting machine has very good cutting effect. Compared with traditional processing, it has obvious advantages of flexible processing, saving time, labor, high efficiency and high precision. As metal laser cutting machines are used more and more widely, they will be applied to laser cutting machines in sheet metal processing, aviation, electronics, electrical appliances, kitchenware and other industries. The following professional laser cutting machine supplier introduces you how to use laser cutting machine to cut good results.

1. The cooling system must be grounded, and the water tank and waterway are often cleaned. The temperature control point of the cooling temperature control water tank must be fair, otherwise the laser tube will be easily damaged and the condensation power will be reduced. The cold water head of the tube will fall off and the life will be greatly shortened. Keep changing tubes.

2. The fulcrum of the laser tube installation of the laser cutting machine should be reasonable. The fulcrum should be 1/4 of the total length of the laser tube. Otherwise, the spot mode of the laser tube will be deteriorated. The light spot will become several points for a period of time, which makes the laser power fall. Meet the requirements, resulting in continuous tube changes.

3. Water protection should always be inspected and cleaned. Cooling water often cannot be used to open the water protection float switch or the water protection float switch is not reset. Short-circuiting methods cannot be used to solve the urgent problem.

4. The suction device should be inspected and cleaned regularly, and the fan ducts should be cleaned. Otherwise, a lot of smoke and dust cannot be discharged, and the lenses and laser tubes are severely and quickly polluted, making the mechanical and electronic parts easily oxidized and causing poor contact.

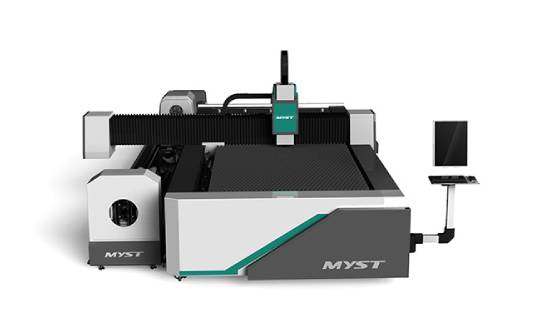

Professional Laser Cutting Machine

5. Focusing lens and reflector inspection, the frame will become feverish after work, the lens surface will become discolored and rusty; peeling and cracking are all the objects to be replaced, especially many customers use air pumps and air compressors, so they focus on Water quickly accumulates on the lens, so it is necessary to check the cleanliness and quality of the lens light path system on time.

6. The working environment of the sheet & tube laser cutting machine should not be too harsh. If the ambient temperature is higher than 30 degrees and lower than 18 degrees, there is too much dust and severe air pollution, so the machine is seriously damaged and malfunction The rate is constantly rising; all electrical parts are prone to problems in humid environments.

Protective measures of metal laser cutting machine

Metal laser cutting machine is a laser cutting equipment specially used for cutting and processing metal materials. It is suitable for the processing of carbon steel, stainless steel, galvanized sheet, etc. The following editors introduce the protective measures of metal laser cutting machine:

1. The air humidity is too high. If water droplets are found on the cover of the generator, and there are watermark marks on the wall of the inspected broken glass tube. You can add high-power air conditioners and air dryers to reduce air humidity; high-temperature air with high humidity may cause glass breakage.

2. There is a large difference between the pressure inside the glass tube and the pressure outside the glass tube. If there is a pressure difference between the inside of the glass tube and the outside of the glass tube, the filling pressure inside the tube can be set the same as the outside of the tube to reduce the possibility of a pressure difference.

3. The mirror of the laser cannot be detached without the special alignment of the optical path (the position of the five mirrors). If the reflector is not removed before the glass tube is replaced, the power should be able to go up after the glass tube is replaced.

The metal laser cutting machine produced and developed by our company has international advanced technology, and the products are exported to foreign countries, and occupy a large market share in major regions.