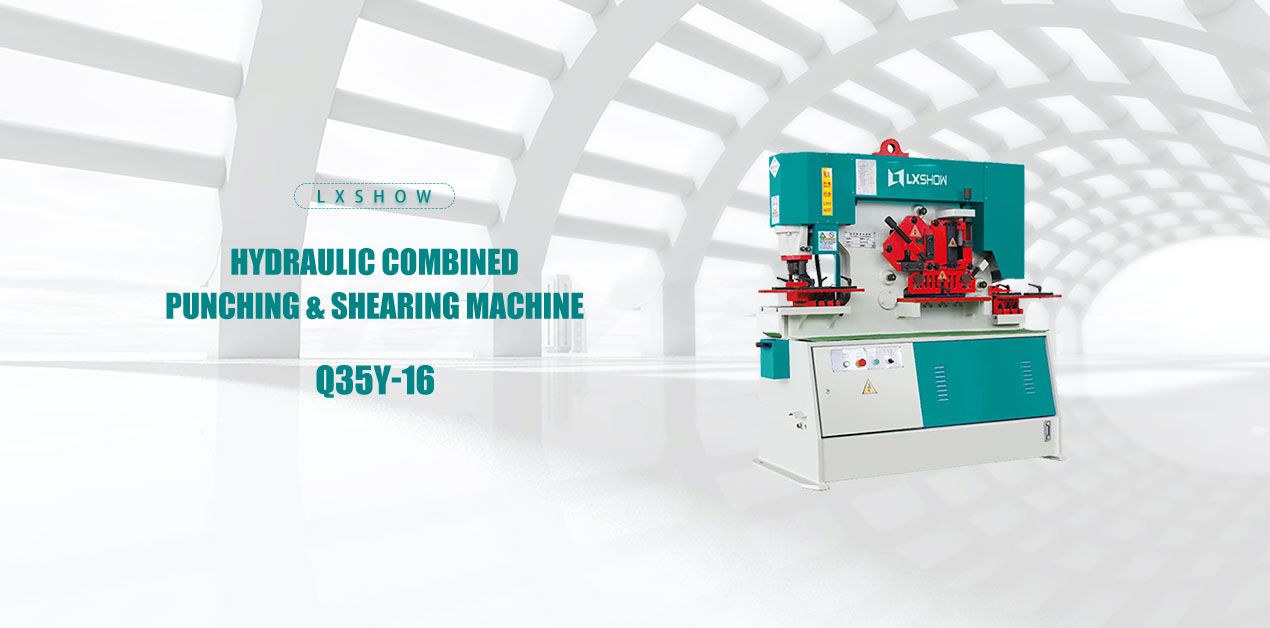

Hydraulic combined punching and shearing machine

Hydraulic combined punching and shearing machines are usually equipped with multiple stations, which can perform punching, shearing and other operations simultaneously or independently, and can realize the shearing, punching and other functions of materials such as plates, square steel, round steel, angle steel, channel steel, I-beam, etc. Some models are also equipped with CNC systems to realize automatic control and improve processing accuracy and efficiency.

Model:Q35Y-16

Dimension (L*W*H)mm:1780*920*1780mm

CBM(m3)/set:2.91CMB

Delivery time:7-15days

Payment:Alibaba Trade Assurance, T/T, Western Union, L/C

Product Advantages

The working principle of the hydraulic combined punching and shearing machine is to drive the hydraulic pump through the motor to generate high-pressure oil,and then distribute the oil to different hydraulic cylinders

through the control valve. The piston in the hydraulic cylinder produces linear motion under the action of oil pressure,driving the punch or shear blade to perform punching and shearing actions.

It adopts hydraulic transmission, and the whole machine has a reasonable structure, light weight, low noise, light and reliable, and has overload performance.

The machine is equipped with punching station, channel steel and angle steel shearing station, thick plate shearing station, round steel and square steel shearing station, and corner cutting station as standard.

It is equipped with five stations and double hydraulic workstations as standard. It can work independently at the same time. The machine does not need any horizontal adjustment, and it can be used after being placed in place.

Technical Parameters

| Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-60 |

| Punching Pressure | 60T | 100T | 120T | 160T | 250T | 315T |

| Max.cutting thickness of steel plates(mm) | 16mm | 20mm | 25mm | 30mm | 40mm | 60mm |

| Material strength(N/mm²) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 |

| Angle of Shear(°) | 7° | 8° | 8° | 8° | 8° | 8° |

| Flat bar shearing(T*W)(mm) | 16mm*250mm 8mm*400mm | 20mm*330mm 10mm*480mm | 25mm*330mm 16mm*600mm | 30mm*335mm 20mm*600mm | 40mm*330mm 20mm*700mm | 50mm*300mm 30mm*750mm |

| Max.length of cylinder stroke(mm) | 80mm | 80mm | 80mm | 80mm | 100mm | 100mm |

| Trips frequency (times/min) | 11-20 | 12-20 | 8-18 | 6-16 | 6-16 | 6-12 |

| Depth of throat(mm) | 300mm | 355mm | 400mm | 600mm | 600mm | 600mm |

| Punch depth(mm) | 16mm | 20mm | 25mm | 28mm | 35mm | 40mm |

| Max.punching diameter(mm) | 28mm | 33mm | 35mm | 38mm | 40mm | 45mm |

| Motor Power(KW) | 5.5KW | 7.5KW | 11KW | 11KW | 15KW | 30KW |

| Overall dimensions(L*W*H)(mm) | 1780*920*1780 | 1950*920*1950 | 2355*1000*2150 | 2840*1200*2330 | 2940*1200*2330 | 3200*1440*2500 |

Main Parts

Punching station

The punching station of the combined punching and shearing machine is a key component

of the equipment, responsible for punching holes of the required shape and size on the metal sheet.

Pressing device

The pressing device of the combined punching and shearing machine is used to fix and press the workpiece during the

punching and shearing process to improve the shearing accuracy and operation safety.

Die cutting station

The die shearing station of the combined punching and shearing machine can be designed with various groove punches according to the shape requirements,

such as rectangular and V-shaped grooves, for shearing and punching of special shapes.

Main motor

The main motor of the combined punching and shearing machine is powered by an AC motor, which has the advantages of low power consumption,

convenient and fast debugging, and fast fault handling.

Oil cooling device

The oil cooling device of the combined punching and shearing machine is used to control and reduce the temperature of the oil when the machine

is working to maintain the oil viscosity and mechanical accuracy.

Collection device

The collection device can collect the processed materials, which is convenient for the staff to sort and improve the work efficiency.

Sample

The hydraulic combined punching and shearing machine has a variety of processing functions, which reduces the equipment switching time and improves production efficiency.

At the same time, the hydraulic system provides stable power output to ensure processing accuracy. It can process a variety of metal materials. It works stably and has high safety.