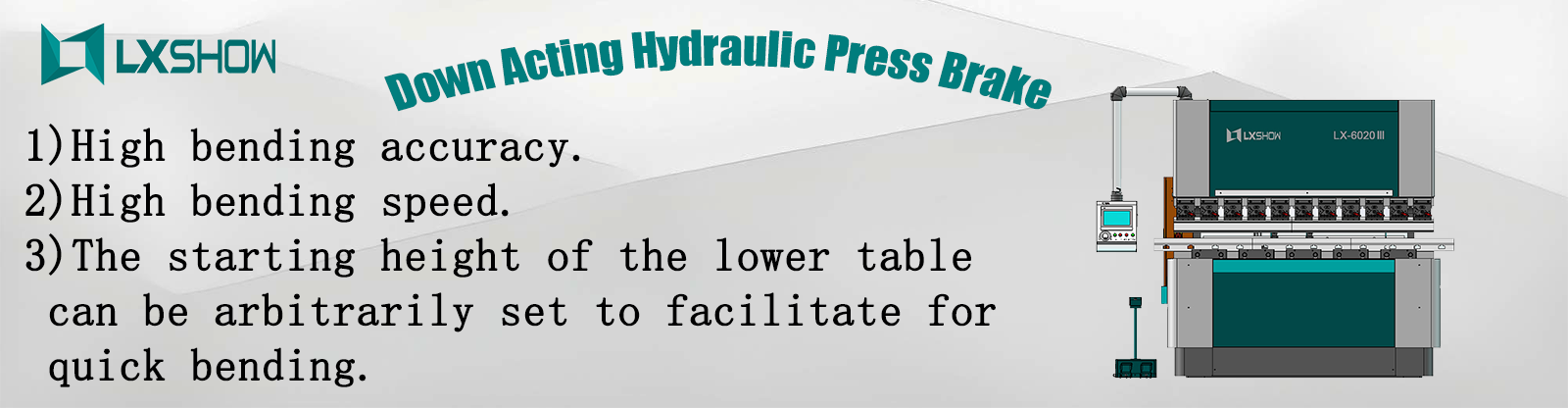

Newly Down acting hydraulic Bending Machine LX-AG-6020

Model:LX-AG-6020

Dimension (L*W*H)mm:2160*1360*2060mm

CBM(m3)/set:6.05m^3

Weight:4000KG

Brand:LXSHOW

Payment:Alibaba Trade Assurance, T/T, Western Union, L/C

After service :Three years

Advantages of down-type bending machine

High bending accuracy, angle accuracy can reach ±0.5 °.

High bending speed, up and down fast forward reaches more than 58mm/s, bending speed is 12mm/s.

With sufficient pressure-applying and pressure-maintaining capabilities, high-strength bending of thick plates and stainless steel can be achieved.

The starting height of the lower workbench can be set arbitrarily, which is convenient for fast bending.

The cylinder only works when bending, and falls back naturally when descending. It is more energy-efficient than the traditional up-type hydraulic type.

The down-working movement during bending makes it easy for the operator to perceive the working status and improve safety.

CNC operating system

System Hardware:

Full color LCD10" TFT widescreen

CPU low power design,quad-core 1.0GHz Intel processor

Power 15W,24V; 1GB ethernet card(RJ45); HDMI.CSI,DSI

Internal storage capacity 4 GB

USB data backup/recovery ;USB 2.0*4 USB3.0*1 flash disk

Support for power off memory

System Advantages:

The interface is simple and easy to use aiming at the continuous improvement of the bending operation mode,

2-axis standard control, maximum support 6-axis .

List-style of input, the interface can change the value at any time

Provides direct dimension input

Provide direct Angle input, any Angle input is obtained, perfect for novice operators.

Supports the automatic arc function

The maximum number of bends per step is 24, which is convenient for combination programming

Supports TEAM VIEWER remote assistance

Connects to an external standard USB camera for monitoring

Powerful diagnostic function and curve detection function

The quick double-sided clamping

The quick double-sided clamping jig for the bending tooling is a fixture manufactured by our corporation.it has good convenience, safety and versatility. It is suitable for most of the products make by mold companies.

When the fixture is used for the bending tooling installation, no need to import from the side. After clamping, the fixture can firmly fix the full-length or segmented tooling.

Installation options are available on inside or outside. No matter which side is installed, the center point of the bending tooling remains unchanged.

When the bending tooling is installed, the red handle of the intermediate plate is in the relaxed position on the left side. When the upper tooling and lower die is centered, the handle can be pulled to the right side to complete the clamping.

Machine frame processing

The frame is welded by the left and right side panels, lower panels, with strength and rigidity.

After strict heat treatment to eliminate stress annealing welding internal stress,so the machine bed has high precision and good stability.

The production process of the frame is all operated by the company itself,which can strictly control the quality.

Bending mold

Upper and lower tooling can be installed with multiple short molds splicing or the whole length mold installation, with high precision, good interchangeability, easy assembly and disassembly.

It is completely universal and interchangeable with the molds used in the bending machine produced by AMADA company.

Retain the down acting AMADA Japan triangle limit system and brake valve

The triangular plate mechanism is a mechanical device to prevent the lower work surface from rushing and to set the bending depth. In order to save costs, manufacturers of the same type cancel the limit mechanism and replaced it with electronic control. For the safety and stability of equipment use, our company still retains.

Servo control is Mitsubishi brand

PLC, depth control and post positioning control servo motor and servo amplifier are made of Mitsubishi products, so that the stroke control has higher accuracy and stability.

Main Motor

High quality, innovative and efficient.

Linear guide back gauge is standard

Linear guide type back gauge is applied to two-axis standard models, manual adjustment of positioning block position, simple and fast. The project of other companies is optional parts.

Foot pedal switch